Specifications applied to steel structure design in the Philippines

Constructions of all buildings require complying with construction regulations to ensure quality and safety. Depending on the specific features and locations of the projects, there are a number of specifications that construction companies must follow. This writing shall explore some of the most common codes and standards applied for steel structure design, especially in the Philippines.

1. An overview of specifications for steel structures design

The purpose of specifications for steel structures design is to ensure that the completed structures are safe and secure and perform effectively.

Depending on the specific project, there are a variety of requirements, but here are some general considerations that are typically taken into account:

- Load capacity: The design must be able to support the weight of the structure, including any loads that may be applied to it, such as wind, snow, or seismic loads.

- Material selection: The type of steel and other materials used in the structure must be selected based on the specific requirements of the project, including factors such as strength, durability, and corrosion resistance.

- Connections: The design must include appropriate connections between the steel components to ensure that the structure is stable and can withstand the loads that will be applied to it.

- Geometry: The geometry of the structure must be carefully considered to ensure that it is stable and can withstand the loads that will be applied to it. This includes determining the shape and size of the steel components, as well as their placement within the structure.

- Fabrication: The design must take into account the fabrication process, including the capabilities of the manufacturing equipment and the skill level of the workers who will be assembling the structure.

- Safety: The design must be safe for workers to assemble and for occupants to use, and must adhere to all applicable safety standards and regulations.

- Aesthetics: The design must also take into account the aesthetic requirements of the project, including any architectural or design considerations.

2. Some common examples of design codes and standards applied to structural building

It is crucial to take international and local codes and standards into account when constructing any building. There are several examples of codes and standards around the world. This part will explore some of the most commonly applied sets.

2.1 US Code

- American Institute of Steel Construction (AISC): The AISC provides standards and specifications for the design, fabrication, and erection of structural steel components, including the Specification for Structural Steel Buildings, the Seismic Provisions for Structural Steel Buildings, and the Code of Standard Practice for Steel Buildings and Bridges.

AISC 360-16 - International Building Code (IBC): The IBC is a model building code that is widely adopted in the United States. It includes provisions for the design and construction of steel structures, including the minimum required design loads, allowable stresses, and connection details.

International Building Code

2.2 Euro, BS code

- Eurocode 3: Eurocode 3 is a set of European design standards for steel structures. It includes provisions for the design of steel components, steel connections, and structural systems, as well as requirements for fabrication and erection.

- British Standards Institution (BSI): BSI provides standards and guidelines for the design and construction of steel structures in the United Kingdom, including the BS EN 1993 series for the design of steel structures.

BS 5920 - 2000

Overall, these are some common examples of specifications applied in the construction industry. It is important to consult with local building officials and industry experts to determine the specific codes and standards that apply to each project.

3. Specifications for steel structure design in the Philippines

Not only must buildings constructed in the Philippines comply with common specifications around the world, but they also need to be suitable to the Philippines' national-specific codes and standards.

3.1 Some examples of codes and standards applied to steel structures in the Philippines

In the Philippines, the following building codes and standards may be applicable to steel structure design:

- National Structural Code of the Philippines (NSCP): The NSCP provides guidelines and requirements for the design and construction of buildings and structures in the Philippines, including requirements for steel structures.

NSCP C101-15 - Philippine Steel Construction Manual: This manual provides guidelines for the design and construction of steel structures in the Philippines, including provisions for load and resistance factor design, allowable stresses, and connection details.

- Philippine National Standard for Steel Structures (PNS 49): This standard provides guidelines and requirements for the design of steel structures in the Philippines, including provisions for load and resistance factor design, allowable stresses, and connection details.

PNS 49-2019 - Philippine National Standard for Welding (PNS 49-1): This standard provides guidelines for the welding of steel components in the Philippines, including requirements for welding procedures, welder qualifications, and inspection and testing of welds.

- Philippine National Standard for Paints and Coatings (PNS 1990): This standard provides requirements for the selection and application of paints and coatings for steel structures in the Philippines, including requirements for surface preparation, application, and performance.

- Philippine Electrical Code: The Philippine Electrical Code provides requirements for the design and installation of electrical systems in buildings and structures, including requirements for grounding and bonding of steel structures.

3.2 Some specific requirements applied for steel structures design in the Philippines

Overall, these requirements may vary depending on specific construction projects. It is important to consult with construction experts to comply with the specifications.

- Design loads: The design loads for steel structures in the Philippines must comply with the requirements of the National Structural Code of the Philippines (NSCP), which specifies the minimum design loads for buildings and structures based on their intended use and location. For example, the design wind loads for steel structures in the Philippines range from 30 meters per second (for low-rise buildings) to 55 meters per second (for high-rise buildings).

- Steel grades: The allowable steel grades for structural steel components in the Philippines are typically specified in the Philippine National Standard for Steel Structures (PNS 49). For example, common structural steel grades include ASTM A36, ASTM A572 Grade 50, and ASTM A992.

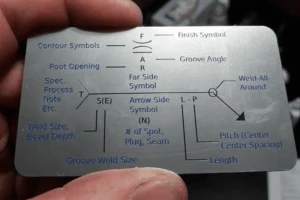

- Welding requirements: The requirements for welding steel components are specified in the Philippine National Standard for Welding (PNS 49-1), which requires that welding be performed by qualified welders using approved welding procedures. The standard also specifies the minimum size and spacing of welds and requires that all welds be inspected and tested for quality.

- Corrosion protection: The requirements for corrosion protection of steel structures in the Philippines are specified in the Philippine National Standard for Paints and Coatings (PNS 1990). The standard requires that steel components be painted or coated to prevent corrosion, and specifies the minimum thickness and type of coating required based on the intended use and location of the structure.

- Connection design: The design of connections between steel components in the Philippines must comply with the requirements of the Philippine Steel Construction Manual. The manual specifies the allowable stresses for different types of connections and requires that connections be designed to resist both tension and shear forces.

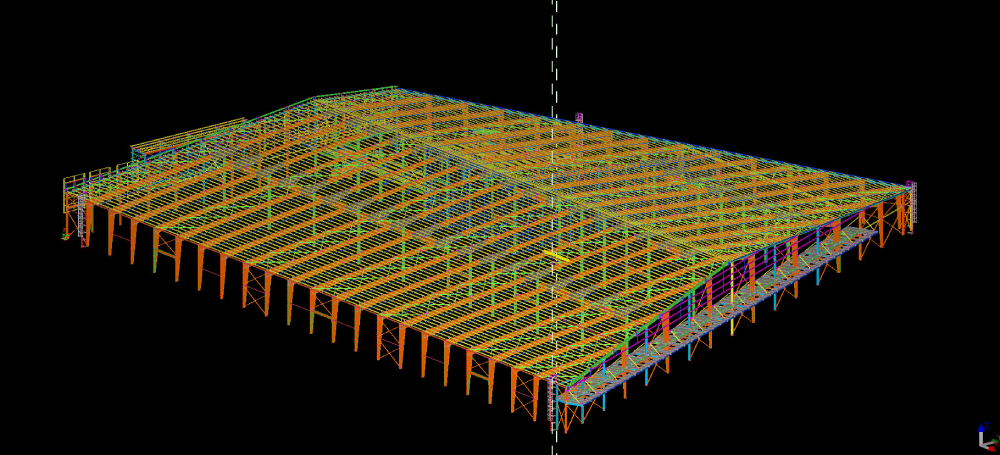

4. BMB’s role as a design consultant

In order to provide clients with qualified design consulting services, BMB Steel always does thorough and adequate research into specifications for steel structures not only in the Philippines but in local areas and around the world. Strictly following these principles helps BMB Steel gain success in a lot of construction projects and gain the trust of customers. This has reinforced the position of BMB Steel in the steel construction industry. We commit to continue working on these principles in order to satisfy our customers not only at the moment but also in the future. Consider using our service and you will not regret the decision.

Above is some information regarding specifications for steel structures design in the Philippines. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.