Standard and safe pre-engineered factory construction process

When building and constructing pre-engineered factories, owners and contractors must carefully understand the construction process’s standards. This will ensure quality and help the project go into use safer and more durable. In the article below, the following information is a standard and safe prefabricated factory construction process for your reference.

1. Advantages of pre-engineered factories

Currently, the pre-engineered factory is the first choice of business enterprises to optimize the construction costs. Besides, this will bring high efficiency in the production process or business activities. This kind of factory includes prominent features such as:

- Lightweight of materials, easy to construct, reduce the load pressure on the whole project

- Useless building materials, save production costs

- Increase the ground and space of the project

- Easy to design, disassemble, repair and expand

- Synchronicity

- High applicability

2. Pre-engineered factory construction process with optimal efficiency

It is indispensable to undergo these specific processes to design and construct a pre-engineered factory with optimal efficiency. There are two main stages:

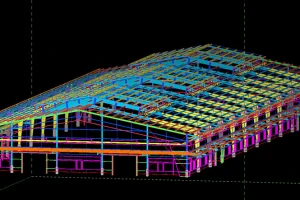

Stage 1: Design of pre-engineered steel buildings (PEBs)

- Research and evaluate the construction site to come up with the optimal design plan

- Make detailed drawings, detailed processing drawings of components

- Choose suitable materials

Stage 2: Machine and manufacture components

- Cut materials

- Manufacture the gusset plate

- Assemble, weld to solidify

- Clean, paint and finish the construction

- Check the safety of the project and put it into use

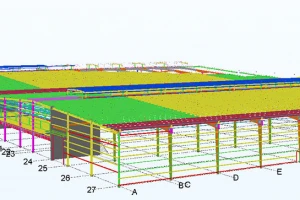

3. The process of building a pre-engineered factory at the construction site

Not only construction engineers but also contractors and business owners need to understand the process of erecting pre-engineered factories at the construction site. This will help you know what stage the construction is in progress and the work quality to check the safety before putting the project into use.

The process of building a pre-engineered factory at the construction site includes:

- Make a plan to check and impulse the work

- Install components such as columns, trusses, beams, corrugated iron, roofs, etc

- Install details such as doors, roofs

- Inspect and repaint components for completed buildings

4. Principles to note in factory construction

In factory construction, we also need to pay attention to some fundamental principles. Compliance with the principles of factory design will ensure the safety of the work for the designers and laborers.

- Before erecting columns, they must be aligned neatly and firmly. Besides, builders also need to combine erecting columns with purlins or bracing walls.

- When installing the rafter frame, we must install it from the inside to the outside, starting from the columns and roofs’ brace

- Use temporary braces during construction and erection

- After building the truss frame and installing the tole, we should pay attention to cleaning and finishing the truss and purlin parts

- Finish the cover, fix and balance the metal sheets

- Carefully complete the roof; you should walk carefully to avoid stamping the tole, causing leaks

- Do not walk on bright tole sheets

The article above from BMB Steel has provided you with the standard and safe pre-engineered factory construction processes. To complete a satisfactory and high-quality project, you should look for a reputable construction contractor. Hopefully, wishing your business to build the most efficient and suitable factory.