Two-story house’s strip footing - Overview and construction instructions

- 1. Overview of the 2-story house’s strip footing

- 2. Design of 2-story house's strip footing

- 3. Construction of 2-story house's strip footing

- 4. Strip footing construction service

- 5. BMB Steel - Solution for constructing 2-story house's strip footings

- 6. BMB Steel - Solution for constructing 2-story house's strip footings

Choosing the right foundation type is extremely important to build a solid structure. The strip footings are one of the most commonly used types of foundations in the construction of houses, factories, and 2-story houses. The 2-story house's strip footings have a simple structure, easy construction and reasonable cost, suitable for many projects.

1. Overview of the 2-story house’s strip footing

The 2-story house's strip footings are of interest to many people because this is a common house model commonly built in Vietnam. Let's learn about this model to get an overview.

1.1 Definition

A strip footing is a foundation located under pillars, columns, and walls to increase the load-bearing capacity of the project. They have the shape of long strips, long parallel rows or intersecting in a cross shape.

1.2 Classification

The 2-storey house's strip footing can be classified into the following types:

Independent strip footing: Each strip footing can only bear the load of one column or group of columns. Independent strip footings can be classified into 2 types:

- Vertical independent strip footing: Strip footings are placed along the length of the building.

- Horizontal independent strip footing: Strip footings are placed horizontally along the width of the building.

Continuous strip footing: The strip footings are connected into a long strip, bearing the load of the entire project. Continuous strip footings can be classified into two types:

- Single continuous strip footing: The strip footings are connected by connecting steel bars.

- Double continuous strip footing: The strip footings are connected by a bonded concrete strip.

1.3 Advantage

The structure of a 2-story house's strip footing has many great advantages such as:

- High load-bearing capacity

- Simple construction, easy-to-check quality

- Reasonable construction costs

1.4 Disadvantage

- The foundation area is large, causing waste of land

- Difficult to construct on soft, muddy ground.

2. Design of 2-story house's strip footing

Designing a 2-story house’s strip footing is an important work before starting construction. It is necessary to calculate which type of strip foundation is most suitable. Some important information below you need to note.

2.1 Factors to keep in mind when choosing a 2-storey house’s strip footings

2.1.1 Type of ground

- For good foundation soil, it is possible to use strip footings to increase sustainability when building a 2-story house.

- If the soft soil layer above is less than 1.5m thin, replace the soft soil layer with a sand cushion, and then construct a normal strip footing similar to good foundation soil.

- In case the upper layer of soft soil is too thick, it is considered a weak soil area. In that case, you should not use strip footings but should use raft footings or pile footings.

- When the soft soil layer has an unstable thickness, strip footings can be used with variable thickness. The foundation will be thicker where the weak soil layer is thick and thinner where the weak soil layer is thin.

2.1.2 Construction load

Strip foundations have a simple structure and construction costs are not too high. Therefore, it is often suitable for projects with average loads. For projects with large loads, pile footings should be given priority.

2.1.3 Construction size and shape

Strip footings are often suitable for projects in the form of townhouses, villas or garden villas... In addition, it is also suitable for other small-sized projects.

2.1.4 Construction costs

Two-story house strip footings are often commonly built in residential projects in Vietnam. This type is considered to have low cost because of its simple and quick construction process.

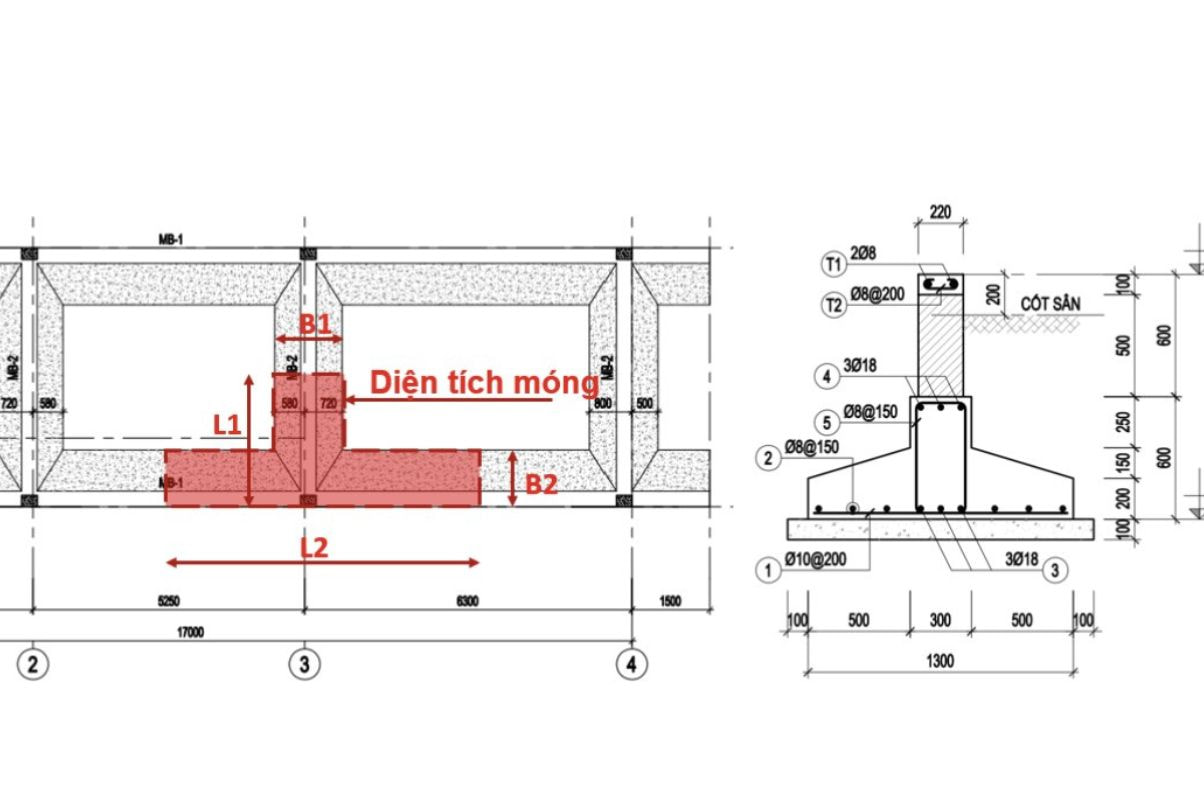

2.2 How to calculate strip footing size

Calculating the size of the strip footing will help you understand the cost of materials. From there, there are more proactive plans for construction.

2.2.1 Independent strip footing size

- Foundation width is determined using the following formula:

Minimum foundation width = 1/2 column width

Maximum foundation width = 1/2 column length

- The foundation length is determined by = 1/2 the column length

2.2.2 Continuous strip footing size

- Continuous strip foundation width is determined as follows:

Minimum foundation width = 1/2 column width

Maximum foundation width = 1/2 column length

- Foundation length = 1/2 column length

2.3 Commonly used materials

Commonly used materials for foundations today are concrete, steel, brick, stone... Depending on the size, load, and foundation soil properties, the number of materials used will vary. Therefore, you can contact BMB Steel if you want to learn more details.

3. Construction of 2-story house's strip footing

After consulting the information about the overview and size of the strip foundation, understanding the process, experience and risks that may be encountered during construction will help the contractors be more proactive in their project.

3.1 Construction process

The strip footing construction process goes through the following basic steps:

- Clearance

First, when constructing a strip footing, you need to clear the site. In this step, it is necessary to clean and tidy the premises. Determine the location to drive piles or dig foundation holes using specialized tools.

- Dicing the hole

After clearing the site cleanly and neatly, it is necessary to dig foundation holes according to the previously marked locations. In this step, you need to strictly follow the drawing, do not dig too shallow or too deep. Normally the depth of the foundation only ranges from 2 to 2.5m and the width is 1.5m.

- Filling the base with sand

Next, depending on the type of soft or good soil, add a layer of reinforced sand. Make sure the hole has a neat, flat foundation for ease of the next construction steps.

- Pouring concrete lining

In this step, we need to pour a concrete lining layer at the pit foundation with a height of 10cm. The purpose is to create a flat surface for the bottom and limit the loss of water from the upper concrete layer during the foundation pouring process.

- Installing reinforcement

This is an extremely important step and needs to comply with the pre-calculated design from the beginning. In particular, it is necessary to comply with the correct spacing between steel layers and between steel layers. At the same time, it is necessary to position the steel carefully so that the moving process does not cause the steel to move.

- Assembling foundation formwork

Next, it is necessary to assemble the foundation formwork. This step also needs to be careful to avoid unnecessary mistakes that will cause the concrete pouring process to not be as effective as desired.

- Pouring a concrete foundation

Pouring concrete for the foundation is an extremely important step when building a cement foundation. The concrete pouring process needs to be carried out according to the design in the drawing. At the same time, the pouring process needs to be even and continuous.

Note that when pouring concrete for strip foundations, you need to pour from far to near, absolutely do not stand on formwork, distorting their structure.

- Maintenance of concrete foundations

After pouring the concrete foundation, you need to avoid physical collisions to avoid cracking or breaking. In addition, it is also necessary to ensure that the concrete is always moist by spreading a tarpaulin and continuously watering it for the first 7 days.

3.2 Construction experience

To construct strip footings with optimal efficiency, contractors need to grasp the following notes:

- Before constructing a strip footing, you should calculate and choose the appropriate type of strip footing. So that they both ensure bearing capacity and help save costs.

- If the foundation has a shallow depth, reinforced concrete foundations should be used.

- It is necessary to survey whether the current ground condition is good or weak before constructing the strip footing.

- When constructing strip foundations, absolutely do not let them be flooded. This will reduce the cohesion and quality of reinforced concrete. Therefore, before pouring concrete, water needs to be absorbed before pouring.

- For projects that require foundations with high bearing capacity, you should use reinforced concrete foundations.

- When constructing strip footings for buildings designed with basement or semi-basement floors, the strip footings need to be placed at least 40cm deeper than the underground ground. The top of the foundation needs to be below the floor of the basement.

3.3 Common risk

Strip footings are known as a popular type of foundation widely used in construction. The design and construction of strip footings need to be carefully calculated before proceeding. However, if this work cannot be guaranteed when building the foundation, you may face several risks such as:

- The footings are not capable of bearing the load due to incorrect calculation or construction on soft ground without additional reinforcement.

- The footings are sinking or tilting due to the ground not being rolled evenly or due to complex terrain.

- The footings crack and break when the materials used when pouring concrete do not meet standards.

4. Strip footing construction service

Currently, the need to build houses, offices... is increasing. Therefore, there are many units providing strip footing construction services. However, to ensure the quality of the strip footings as well as construction costs, the contractor wants to find a reputable unit.

One of the units most trusted by business owners, contractors, and homeowners today is BMB STEEL. This is a company specializing in the design and construction of large tonnage factories. Therefore, they can construct strip footings for houses and offices extremely well and bring optimal efficiency.

Currently, BMB STEEL is being selected by Cheng Loong Co., Ltd. as a construction partner with 4 main items. Which includes BM2 powder-making plant, grinding room, main power plant, packaging workshop. The project has a total area of up to 63,000 m2 and uses nearly 1,500 tons of steel.

This is a project with extremely large loads, so the foundation design and construction stage are extremely important. However, with a team of professional engineers, all problems will be handled quickly and optimally by BMB STEEL. Therefore, if you need to design a strip footing or any pre-engineered steel construction project, you can immediately contact BMB STEEL for quick support.

Strip footing construction service

5. BMB Steel - Solution for constructing 2-story house's strip footings

During the construction of strip footings, many problems can occur if not carefully calculated. Therefore, you will need to refer to quick and thorough solutions.

5.1 The solution to fix the 2-story house's strip footing not being strong enough

The reason this situation occurs is due to not carefully studying the ground or generating loads that exceed the originally designed level. If you want to fix it, you must reinforce the house's foundation by expanding the bottom of the foundation.

This means we need to fabricate additional support structures under the old foundation. The simplest way is to add a reinforced concrete slab under the old foundation. Thus, the ice foundation will be firmly reinforced and can withstand greater force.

5.3 The solution to fix cracked and collapsed strip footings

During the construction of the strip foundation, if standards are not followed, it can lead to cracked and collapsed strip footings. The cause may be due to a change in ground structure. However, it is mostly due to:

- Not carefully surveying the terrain and miscalculating the structure.

- The construction unit incorrectly implemented the design drawings and did not comply with technical specifications.

- The investor saves materials or does not design the product according to the required functionality.

When cracks and corks appear, they can put your project in danger during use. Fixing this problem is also quite complicated. We need to have a realistic observation to see what level of subsidence and collapse is at, what is the cause, to have timely remedial measures:

- If the cracks only last for a certain period and stop, you can wait and do light repairs.

- If the crack is only small in the house, you can remove the brick or cement layer and replace it with a little soil to fill it and reinstall the new brick. If subsidence occurs on the balcony or house columns, you need to find a way to reduce the pressure on the foundation before dealing with the settlement.

- In addition, in case of severe collapse, you need to seek experts for reinforcement. One of the most active and effective measures is to strengthen the foundation. It may even be necessary to lower the high column or raise the lower column...

6. BMB Steel - Solution for constructing 2-story house's strip footings

It can be said that repairing and overcoming strip footing errors is extremely complicated. Not only is it unsightly and time-consuming, but it also costs a lot of money.

To avoid these situations from the beginning, you should find reputable construction units. These units often have a team of professional workers who design accurate drawings. The materials provided are of good quality and have a warranty after construction. Thus, the new project can be sustainable and stable with a long lifespan even after a long period of use.

If you are an investor, homeowner, or business owner looking for a unit to construct 2-story house’s strip footings, BMB Steel will be the perfect choice. With a team of skilled engineers and professional calculation software, we will help you have a solid foundation without worrying about cracking over decades.

Coming to BMB Steel, you will receive detailed advice on all issues. From there, you can understand the construction costs and stability of the project. All proposed plans are aimed at meeting all customer requirements.

Depending on the terrain, you will also receive more detailed advice on the appropriate type of strip footing. This helps save costs while still getting the optimal item, ensuring quality and suitability for use.

Above is information about the construction of 2-story house's strip footings. If you have any questions, please contact the hotline at 0767676170 immediately to receive detailed advice from the team of engineers and specialists at BMB Steel.