Built-up steel: Features & applications in construction

Built-up steel is becoming a top choice in construction projects thanks to its outstanding durability, high load-bearing capacity, and design flexibility. Join BMB Steel to explore what built-up steel is, key features, common types, production process, practical applications, and the latest fabrication price list.

1. What is built-up steel?

Built-up steel is manufactured by cutting from steel plates and then assembling them into shapes and sizes according to technical drawings. This process is usually carried out through welding, joining the cut plates from the steel billet to create components with specific dimensions and shapes.

A standout feature of built-up steel is its exceptional flexibility in design, size, and thickness, which is almost unlimited and can be easily customized to suit various types of projects and the specific requirements of each client. With a solid structure and high load-bearing capacity, built-up steel not only ensures the stability of the structure but also accelerates construction progress while optimizing material costs.

Xem thêm: Drawings of pre-engineered steel buildings trending in 2021

2. Characteristics of built-up steel

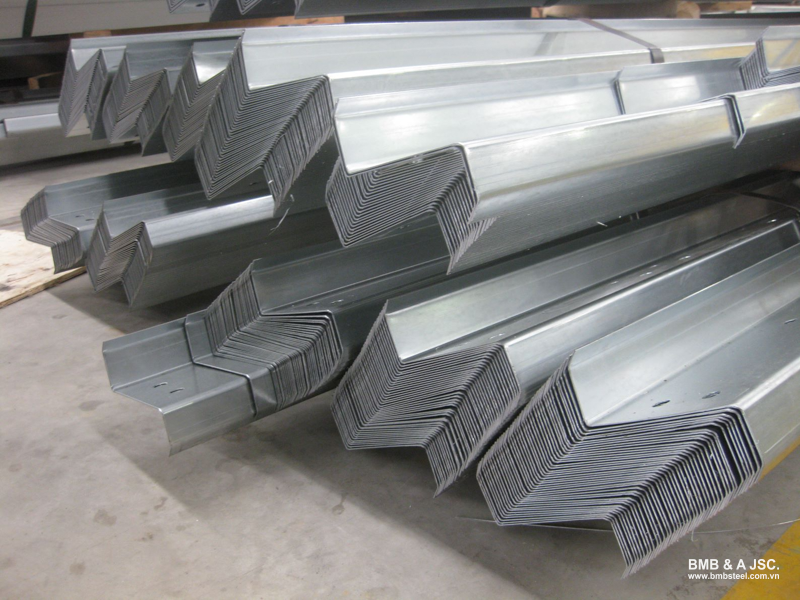

Built-up steel products are commonly manufactured in H-beam and I-beam forms. However, since they are fabricated from steel plates, customers can fully request production in any desired shape and size. Below are the key characteristics of built-up steel:

- Variety and flexibility in size: Built-up steel can be fabricated according to the specific technical requirements of each project. Unlike conventional rolled steel, it is not limited by shape or size, offering maximum flexibility in design and application.

- High load-bearing capacity: With excellent quality and superior strength, built-up steel is an ideal choice for projects requiring high durability and heavy load-bearing capacity, especially in industrial and heavy construction sectors.

- Low deflection: Large dimensions combined with a solid structure help built-up steel minimize deflection, ensuring stability and safety for the structure.

- Lightweight and cost-efficient: Manufactured precisely according to design specifications, built-up steel optimizes material usage, reduces the overall weight of the structure, and significantly lowers construction costs.

3. Classification of built-up steel

Built-up steel can be classified according to various criteria, with the most common method being classification by cross-section. Specifically, the typical types of built-up steel include:

- U-beam steel: Features a U-shaped cross-section, with moderate flange height compared to the web width, suitable for many construction applications.

- I-beam steel: Features an I-shaped cross-section. In some cases, H-beams are also considered a type of I-beam, with the main difference lying in the relative proportion between the flange width and the web height. Commonly used in bridge construction, high-load-bearing capacity structures.

- V-beam steel: Has a V-shaped cross-section, with 2 flanges of equal width, often used in special geometric structures to enhance mobility and resistance to crushing.

- L-beam steel: Has an L-shaped cross-section, where the flange width is smaller than the web length, making it suitable for wall framing, secondary structures.

Depending on the specific requirements and characteristics of each project, built-up steel products are available in a wide range of sizes, shapes, and applications, fully meeting the diverse needs of customers.

4. Built-up steel manufacturing process

The manufacturing process of built-up steel involves a series of complex steps that require high precision and strict quality control. Below are the detailed steps:

Step 1: Inspection of incoming materials

This is a crucial step to ensure product quality. Inspection activities include:

- Verifying the origin of materials and quality documentation.

- Comparing and cross-checking the material’s technical specifications with project requirements.

- Ensuring the material standards comply with current construction codes.

- Sampling and testing material quality. If required, use an independent laboratory for verification. Only materials that meet the requirements will be processed for production.

Step 2: Steel cutting

Depending on the equipment available, steel plates are cut using CNC plasma cutting machines, punching machines, etc. After cutting, the steel is straightened and shaped according to technical drawings to produce components such as H, I, V, U, L sections, etc.

Step 3: Built-up welding

Flange plates and web plates are automatically welded using specialized welding machines. Welds are inspected by visual examination, magnetic particle testing, ultrasonic testing, etc., to ensure proper technique and quality.

Step 4: Inspection and straightening

After welding, steel members are checked and straightened to correct any deformation or misalignment caused by heat during the welding process.

Step 5: Welding end plates and stiffeners

These parts are manually welded to achieve absolute precision. This step requires certified welders with high skills.

Step 6: Surface cleaning and shot blasting

Steel members are cleaned and rust is removed using shot blasting machines to prepare for coating.

Step 7: Coating

Built-up steel is coated with protective layers such as fireproof paint, anti-corrosion paint, decorative finishes to ensure durability and aesthetics.

5. Applications of built-up steel in construction

Thanks to its outstanding load-bearing capacity, structural strength, and design flexibility, built-up steel is extensively applied across various construction and industrial projects, including:

- Pre-engineered steel buildings: Built-up steel is the main material for structural frames, providing high durability and excellent load resistance.

- Large-span structures: For bridges, stadiums, or large-scale canopies, built-up steel allows for optimized structural design and reduced overall weight.

- High-rise buildings: Built-up steel structures enhance load capacity, vibration resistance.

- Bridges and transportation infrastructure: The exceptional strength and load-bearing capability of built-up steel ensure the safety of these structures.

- Projects requiring dynamic load resistance (railway stations, airports, etc.): Built-up steel structures offer high adaptability, ensuring long-term stability against dynamic loads and environmental impacts.

6. Built-up steel fabrication price list

The cost of fabricating built-up steel and structural steel depends on multiple factors such as steel type, component size, plate thickness, coating requirements, welding standards, order volume, and construction schedule.

Below is a reference price list for built-up steel fabrication:

|

Fabrication item |

Unit price (VND/kg) |

Notes |

|

Built-up steel fabrication (I-beams, H-beams, columns) |

8,500 – 11,000 |

Depends on technical requirements and quantity |

|

CNC steel plate cutting |

1,000 – 1,500 |

Calculated per meter cut or kg |

|

Automatic submerged arc welding (SAW) |

2,000 – 2,800 |

Priced separately if the client already provides the steel billets |

|

Epoxy anti-rust coating |

1,200 – 1,800 |

Depends on the number of coating layers and project standards |

|

Weld inspection (upon request) |

Negotiable |

Can include ultrasonic testing, dye penetrant testing, or tensile testing |

|

Gusset plate, bracing, connection fabrication |

10,000 – 15,000 |

Based on complexity and quantity |

|

Structural steel fabrication (cutting, punching, drilling) |

8,000 – 10,000 |

For I, H, U, V sections, etc. |

Note: Actual prices may vary depending on order quantity, required timeline, and on-site construction conditions.

Built-up steel not only offers a durable structural solution but also optimizes design and cost for various types of projects such as factories, bridges, large-span constructions, high-rise buildings, etc. With its variety in size, shape, and the ability to be custom-fabricated, built-up steel meets diverse technical standards with flexibility. When making a selection, investors should consider reputable suppliers to ensure both product quality and construction efficiency.

As a leading company in the steel structure industry, BMB Steel’s experts are ready to provide consultations and competitive quotes for high-quality built-up steel tailored to each client’s specific needs. We are committed to precise construction, on-time delivery, and helping clients achieve optimal investment efficiency.