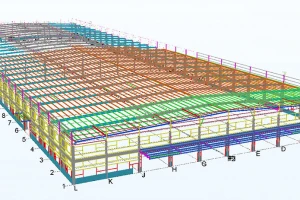

Design solutions for sustainable pre-engineered steel building

Sustainability is always one of the concerns of enterprises when it comes to constructing a building. Since the construction of pre-engineered steel buildings is new terminology, there is still room for construction enterprises to do the investigation into sustainable solutions for this type of building. This article shall discuss some effective design solutions which make pre-engineered construction more sustainable than conventional steel structures.

1. Sustainable pre-engineered steel building

Sustainability has always been a priority in the construction industry worldwide. A pre-engineered steel building is considered sustainable based on several aspects. First of all, it does not require a huge amount of material, energy, and space during construction and in use. Secondly, it does not deteriorate under the attack of different factors, such as harsh weather, terrain, disasters, and so on. Finally, it can be reused and recycled and does not cause the environment huge pollution after use.

2. Sustainable features of pre-engineered steel building

There are a variety of reasons why pre-engineered steel building appears to be more sustainable compared to conventional buildings. This part of the article will focus on three terms, including frame weights, lateral displacements (sway), and vertical displacements (deflection) of the frames.

2.1 Frame weight

First of all, with the same length of span frame, same bay pacing, and under the same load, it is estimated that the frame of a pre-engineered steel building is lighter compared to that of a conventional steel building. Research by some Saudi Arabian scientists pointed out that with a span length of 30 meters and bay pacing of 6 meters, it was found that a pre-engineered steel building’s weight was around 30% lower than that of conventional buildings. For longer spans or larger bay pacing, it was proved that the frame weight was reduced at a larger rate.

2.2 Lateral displacement (Sway)

In addition to frame weight, lateral displacement, also known as sway, is a factor that makes the pre-engineered steel building more effective at bearing load compared to traditional systems. Sway structures are known for being flexible and are designed to be subject to wind, earthquakes, and other types of dynamic loading. It was proved that pre-engineered steel buildings appeared to be less in terms of sway compared to conventional steel structures. This is due to the application of better cross-sectional sizes and tapering steel sections method in the design of the construction.

2.3 Vertical displacement (Deflection)

Similar to lateral displacement, vertical displacement is also taken into account when considering sustainable construction. In construction, deflection refers to the amount of bending or deformation that a structure or material experiences under load. This can include things like the amount of sag in a beam or the amount of bend in a column. The pre-engineered steel frames showed lesser vertical displacements compared to conventional hot-rolled steel frames.

3. Design solutions for sustainable pre-engineered steel building

As aforementioned, there are factors that are taken into consideration when constructing a sustainable pre-engineered steel building. This part of the article shall focus on the design process, analyzing two methods that lowers seismic and gravitational forces as well as minimizes production, and construction. and transportation costs.

3.1 Cross-sectional sizes

Typically, pre-engineered steel buildings use a combination of hot-rolled and cold-formed steel members. Hot-rolled steel members are typically used for primary structural elements like columns and beams, which are subject to high loads and stresses. Cold-formed steel members, usually using different processes like rolling and pressing, are used for support structures like purlins and girts that help hold up the roof and walls. The sizes of cold-formed steel members are usually smaller than hot-rolled members, but they are still strong enough to bear loads. Better control over cross-sectional sizes in designing pre-engineered steel buildings can help reduce a large amount of material and energy.

3.2 Tapering steel section method

Tapered steel sections are used to reduce the weight of the building, improve its aesthetic appeal, and optimize its structural performance. The most common method for producing tapered steel sections is the rolling method. This method involves passing a steel beam or column through a series of specially designed rollers that gradually reduce the width and thickness of the section along its length. Other methods for producing tapered steel sections include cutting and welding which is typically more time-consuming and expensive than the rolling method. Better control over the use of tapered steel sections is a good choice to reduce costs and energy.

Above are some design solutions for sustainable pre-engineered steel building construction. Hopefully, this article has provided you with useful information. Visit BMB Steel’s website to read more about pre-engineered steel buildings and steel structures. You can also contact us for design consulting and steel production services.