Steel frame factory: Smart and cost-effective choice

- 1. What is a steel frame factory?

- 2. Structure of steel frame factory

- 3. Advantages, disadvantages of steel frame factory

- 4. Comparison between steel frame factory and reinforced concrete buildings

- 5. Construction guide for steel frame factory

- 6. Latest construction costs for steel frame factory

- 7. Modern and durable steel frame building models

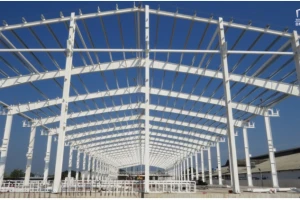

As construction demands continue to diversify, steel frame factories are emerging as a leading trend in modern construction. Known for their fast installation and cost-efficiency, these structures also stand out for their durability, flexibility, and ease of expansion. Steel frame factories are proving to be a superior alternative to traditional building methods. In this article, BMB Steel provides a comprehensive overview of steel frame factories, including their structure, pros and cons, construction process, popular design models, and the latest cost updates.

1. What is a steel frame factory?

A steel frame factory is a type of structure assembled from steel components that are pre-manufactured in a factory. The construction process follows a specific technical drawing, ensuring high precision and significantly reducing construction time.

In addition to the term steel frame factory, this type of construction is also known by other names such as pre-engineered steel buildings, modular steel buildings, prefabricated steel structures, etc.

Today, steel frame factories are increasingly applied in various construction projects. Not only are they commonly used in factories and warehouses thanks to their large-span capability and flexibility, but they are also widely found in major urban areas: supermarkets, showrooms, restaurants, high-rise buildings, etc.

2. Structure of steel frame factory

Foundation

The foundation is responsible for transferring the entire load of the steel frame factory to the ground. Thanks to the lightweight nature of steel structures, the foundation in prefabricated steel buildings is typically simpler than that of traditional reinforced concrete structures. Depending on the soil conditions and the scale of the project, different types of foundations can be used such as pad foundations, strip foundations, raft foundations, or pile foundations.

An important factor during the foundation construction phase is the installation of anchor bolts. These bolts must be positioned accurately within the steel base before concrete is poured. If the bolts are misaligned, the erection of steel columns and beams later on will be difficult and could affect the integrity of the entire structure. Common bolt sizes are M24 or M27.

Floor slab

The floor slab in the steel frame factory serves to provide usable surface area while also distributing the load from equipment and occupants down to the foundation. Common materials include reinforced concrete, combined with a moisture-proofing layer and a surface finish that suits the function of the building.

The floor construction process includes: site leveling and soil compaction, pouring a lean concrete base, placing floor reinforcement, and then pouring the main concrete layer. Depending on usage needs, the floor may be reinforced with steel fibers, coated with epoxy, or treated with waterproof paint to enhance durability and ease of maintenance.

Main structural frame

The main frame is the primary load-bearing component of steel frame factories, consisting of vertical columns, rafter and horizontal beams. Common materials used include H-shaped, I-shaped, or built-up steel beams. Connections between columns and rafter, beams are made with base plates and high-strength bolts, ensuring stability, load resistance, and vibration control during operation.

Skylights and canopy roofs

Skylights are installed along the roof ridge to allow air circulation, vent hot air, maintain a well-ventilated interior space.

Canopy roofs are small roof sections placed above doorways or windows, designed to block sunlight, shield against rain, and protect the surrounding areas from weather elements.

Purlins and bracing systems

Purlins support the corrugated steel roof and are typically made from galvanized Z or C-shaped steel, spaced around 1-1.5 meters apart. Purlins help evenly distribute roof loads to the main frame, contributing to the overall stability of the structure.

The bracing system includes roof bracing, column bracing, and purlin bracing. While these elements don’t account for a large portion of the structure’s weight, they play a crucial role in stabilizing the frame, minimizing vibrations, and preventing deformation. Missing or poorly designed bracing systems can compromise the safety and lifespan of the steel building.

Cladding and insulation materials

The cladding is the outermost layer of the steel frame factory, designed to protect the structure from environmental elements such as sun, rain, and wind, etc. It also enhances the building’s appearance, giving it a modern and professional look.

The most common type is single-layer color-coated steel sheeting, known for its good corrosion resistance. However, in hot climates, the roof is often supplemented with insulation layers to reduce heat, limit noise, ensure a comfortable interior environment.

3. Advantages, disadvantages of steel frame factory

3.1. Advantages

- Fast construction time: steel frame factories are assembled from prefabricated components produced in factories. These components only need to be installed on-site, which significantly shortens the construction period, reduces labor costs, and minimizes material waste.

- High flexibility: Steel frame structures are easy to expand, upgrade, dismantle, or relocate without affecting the main structure.

- Excellent load-bearing capacity: Steel has high strength and durability, capable of withstanding heavy loads and harsh environmental conditions. This makes the steel frame factory suitable for both residential and large-scale industrial projects.

- Optimized use of space: With the ability to span long distances without intermediate columns, steel frame factories offer spacious, open interiors that enhance usability and comfort.

- Aesthetic appeal: Modern steel structures can be combined with glass, wood, or other decorative materials to create a minimalist, elegant, impressive exterior.

- Environmentally friendly: Steel is highly recyclable. Using a steel frame factory helps reduce construction waste and supports sustainable development.

3.2. Disadvantages

- Susceptible to corrosion: In humid, coastal, or chemically aggressive environments, steel structures are prone to oxidation. To ensure durability, they must be coated with anti-rust paint and undergo regular maintenance.

- Limited fire resistance and insulation: At high temperatures, steel can lose its load-bearing capacity, compromising the safety of the building. Additionally, steel is a strong conductor of heat, making interior spaces prone to overheating and increasing cooling costs during hot seasons. To improve fire resistance, the steel frame should be protected with fire-resistant materials such as concrete, ceramic boards, and fireproof coatings. Buildings should also be equipped with proper fire protection systems to ensure safety in case of emergency.

4. Comparison between steel frame factory and reinforced concrete buildings

|

Criteria |

steel frame factory |

Reinforced concrete buildings |

|

Design & construction |

Components are pre-manufactured in the factory and assembled on-site using bolts. |

Shaping is flexible. Construction is done by pouring concrete directly on-site. |

|

Construction cost |

Up to 50% faster construction, saving around 15-25% in costs due to reduced materials and labor. |

Higher cost for labor and materials (cement, bricks, sand, steel, etc.). Longer build time increases extra costs. |

|

Building lifespan |

Lasts 50-100 years or more with proper maintenance. Termite-resistant and less prone to cracking. |

Average lifespan is 30-40 years, potentially up to 100 with premium materials. Susceptible to aging in humid climates. |

|

Upgrade potential |

Easy to upgrade by adding pre-made components; old structures often have bolt holes for expansion. |

Adding floors or expanding requires drilling, breaking, adding columns, which is time- and labor-intensive. |

|

Aesthetic flexibility |

Modern and minimalist designs. With skilled architects, it can achieve a refined and impressive appearance. |

Can feature complex shapes and decorative patterns. Suitable for highly artistic architectural styles. |

|

Construction time |

Takes only a few weeks to a few months. Complex details (if any) are processed at the factory. |

Typically takes 6 months to 1 year depending on scale. All stages are carried out on-site, requiring more time. |

|

Moisture resistance |

Good moisture resistance thanks to effective drainage systems and water-resistant materials. |

Concrete retains water and can absorb moisture if built or maintained improperly. Requires careful treatment. |

|

Fire resistance |

Steel doesn’t burn but loses strength above 280°C. Fire resistance can be improved using coatings, cladding, etc. |

Concrete transfers heat slowly and resists fire well. However, its strength can degrade between 450-650°C. |

|

Load-bearing capacity |

Excellent tensile, compressive, bending strength. Lightweight with small cross-sections yet high capacity. |

Concrete (compression) and steel (tension) work together to create strong structures if properly constructed. |

5. Construction guide for steel frame factory

After the manufacturing process is completed, the steel components are transported to the construction site for assembly. Below are the basic construction steps:

Step 1: Positioning and installing anchor bolts

This is the initial and most critical step in constructing a steel frame building. Anchor bolts must be positioned accurately according to the technical drawings, as they connect the foundation to the steel framework above.

Step 2: Erecting columns, beams, and trusses

Next, the construction team installs the main structural frame, including steel columns, horizontal beams, and roof trusses. These components are connected using high-strength bolts and base plates to form the main load-bearing system of the building.

Step 3: Installing purlins

Purlins are installed to connect the roofing system to the main frame. Purlins are typically Z- or C-shaped and are spaced according to technical specifications to evenly distribute the roof load across the entire structure.

Step 4: Installing the metal roofing sheets

The metal roofing provides protection from sun and rain while enhancing the building’s overall aesthetic appearance.

6. Latest construction costs for steel frame factory

The cost of building a prefabricated steel frame structure does not have a fixed price, as it varies depending on the specific features and requirements of each project. Some key factors that influence the total investment include:

- Construction area and scale.

- Quality and type of materials used.

- Labor costs in each region.

- Equipment, machinery for construction.

Below are the current market prices:

Cost per floor area:

|

Type of project |

Unit price (VND/m2) |

|

Turnkey 2-storey residential steel frame house |

3.000.000 - 3.300.000 |

|

Warehouse/factory under 1.500m2 |

1.200.000 - 2.000.000 |

|

Factory from 3.000-10.000m2 |

1.400.000 - 1.700.000 |

|

Factory over 10.000m2 |

1.100.000 - 1.500.000 |

Cost per construction item:

|

Construction item |

Unit price (VND/m2) |

|

Structural work |

1.200.000 - 2.000.000 |

|

Finishing work (including roof, walls, interior, exterior) |

2.500.000 - 4.500.000 |

The above prices are for reference only and may vary depending on the time, location, and project characteristics. For the most detailed and accurate quotation, please contact BMB Steel - a trusted design and construction company for steel frame factory, for consultation and an on-site survey.

7. Modern and durable steel frame building models

Single-story steel frame factory for cost savings

This is a popular model used in both residential construction, small warehouses, workshops. With a simple design, cost-effective construction, easy installation, it suits small to medium-sized land lots. The steel frame provides good load-bearing capacity, combined with metal roofing and panel walls to create a well-ventilated and long-lasting structure.

Two-story steel frame factory for space optimization

This model is favored by many families and businesses for its ability to optimize space. The upper floor layout is flexible and can be used as an office, residential area, and medium-scale production space. Two-story steel frame factories are quick to construct, easy to expand, and more cost-effective than traditional concrete structures.

Steel frame factory with mezzanines

This is an ideal option for residential homes, homestays, small guesthouses. A mezzanine adds usable living space without increasing the building’s footprint. With a sturdy steel frame and lightweight materials, this model still ensures durability and aesthetics over the long term.

Large-span steel frame factories

Typically used in industrial parks, large-scale manufacturing plants. These steel frame factories are designed with wide spans to create open production spaces without internal partitions. This facilitates the arrangement of machinery and production lines. The roof can be integrated with ventilation systems, natural lighting, effective insulation.

Simple prefabricated steel warehouses

Steel frame warehouses are usually designed as open spaces without partitions to maximize storage capacity. The high load-bearing steel frame ensures safety for heavy and bulky goods. Additionally, quick construction and low cost are key reasons why this model is widely preferred.

Prefabricated modular steel offices

Steel frame factories used as offices often feature a modern exterior, incorporating glass, wood, soundproof materials. The interior space is arranged flexibly with lightweight partitions that are easy to modify when needed. This is a suitable solution for small businesses, startups, or temporary offices at construction sites.

Steel frame factories are not only the optimal choice for industrial projects but are also gradually establishing their place in modern residential construction. With numerous advantages such as fast construction, reasonable cost, durable structure, high aesthetics, this building type is opening up a new direction for those seeking a flexible, efficient, and environmentally friendly construction solution. If you are planning to build a factory, warehouse, office, contact BMB Steel for in-depth consultation and full-service support from design to construction.