The history of steel structure development in the world

In the journey of architectural and construction development, the history of steel structure development has always been marked by significant milestones, giving rise to some of humanity’s most iconic landmarks. Steel structures are not only a durable building material but also a foundation that enables people to conquer new heights, expand spaces, and create sustainable, modern projects. In this article, BMB Steel will walk you through the remarkable milestones while exploring the immense potential and diverse applications of steel structures in today’s construction landscape.

1. The evolution of steel structures

The history of steel structure development reflects the remarkable journey of architecture and engineering over the past centuries. Each milestone not only demonstrates technological progress but also emphasizes steel’s vital role in meeting society’s needs. The following sections highlight the most important milestones that defined each stage of this evolution.

1.1. Early exploration (late 18th - 19th century)

Back in the late 18th century, the use of metal in construction began to revolutionize architecture. Britain was the pioneer in integrating cast iron into buildings and infrastructure, thanks to its superior strength and fire resistance compared to wood and stone.

A notable milestone of this era was the Iron Bridge in England (1779), the world’s first bridge made entirely of cast iron. This achievement demonstrated the ability of metal to support heavy loads and span wider distances than traditional materials, opening new possibilities for future architectural innovation.

During the 19th century, industrial advancements accelerated the shift from cast iron to structural steel. Wrought iron and steel became the preferred materials, offering greater flexibility, higher strength, and reduced brittleness. Several key developments marked this transition:

- 1820 - First Cast Iron Building (Philadelphia, USA): The beginning of metal-framed buildings beyond bridges and factories.

- 1828 - First Steel Bridge (Vienna, Austria): A breakthrough that showcased steel’s superior performance over cast iron in bridge construction.

- 1851 - The Crystal Palace (London, UK): A revolutionary glass-and-iron exhibition hall that popularized prefabricated components and modular construction.

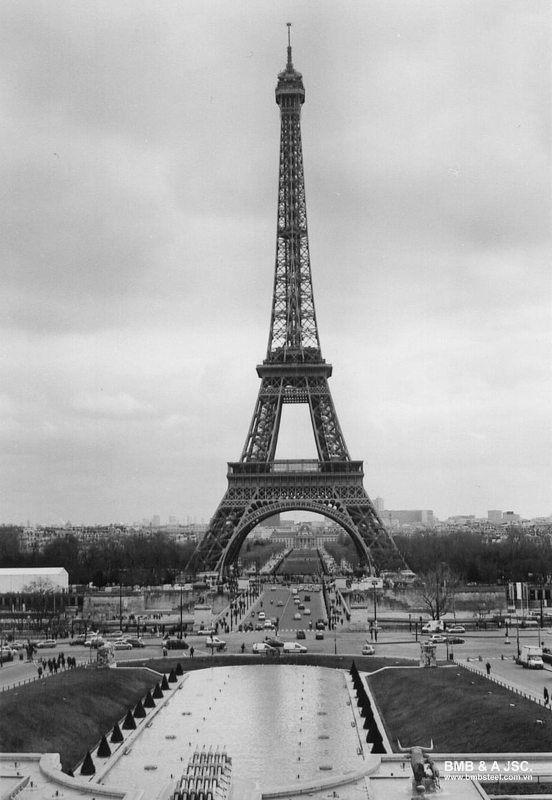

- 1876 - The Eiffel Tower (Paris, France): At 300 meters tall and built with 7,000 tons of iron, it proved metal’s potential for monumental, freestanding structures.

- 1889 - The Rand McNally Building (Chicago, USA): Recognized as the first all-steel skyscraper, it marked the beginning of modern high-rise construction.

By the end of the 19th century, steel had firmly replaced iron as the dominant material in ambitious projects. This evolution transformed bridges, skyscrapers, reshaped urban landscapes worldwide, setting the stage for the rapid expansion of steel structures in the 20th century.

1.2. Emergence of steel structures (early 20th century - pre-WWII)

At the beginning of the 20th century, steel had already become the foundation of modern construction. With advancements in steel production and structural engineering, architects were able to challenge the limits of height and complexity, giving rise to the first generation of skyscrapers.

- 1909 - Berlin Turbine Factory (Germany): Designed by Peter Behrens, this factory is often considered the first modern building. It demonstrated the structural efficiency of steel and adopted a functionalist approach, breaking away from traditional decorative architectural styles.

- 1931 - Empire State Building (New York, USA): Rising 102 stories (381 meters), the Empire State Building became a new icon of skyscraper design. Completed in just over a year, it stood as the tallest building in the world at the time and highlighted the decisive role of steel in shaping high-rise architecture.

By the years leading up to WWII, steel had established itself as the essential material for skyscrapers and large-scale projects, paving the way for even taller and more sophisticated structures in the following decades.

1.3. Post-WWII expansion of steel structures (mid-20th century - late 20th century)

Following World War II, rapid urbanization, industrial growth, and global economic expansion created unprecedented demand for stronger, taller, and more innovative steel structures. This era marked the rise of high-rise buildings, long-span roof systems, space-frame structures, and hybrid designs combining steel with concrete.

1950s - 1960s: Post-war growth and innovation

- 1953 - Raleigh Arena (USA): Recognized as the first suspended roof building, it marked a breakthrough in long-span design, showcasing steel’s flexibility in creating lighter and more efficient roofs.

- 1960s: Skyscrapers grew taller, space-frame systems emerged, and composite steel-concrete structures gained momentum. Prefabrication techniques also accelerated construction speed and reduced costs, making steel more competitive worldwide.

1970s - 1990s: The era of super-tall steel structures

- 1970 - World Trade Center (New York, USA, 410m): The twin towers became a global symbol of engineering innovation, utilizing a tube-frame structural system for exceptional strength and stability.

- 1973 - Sears Tower (Chicago, USA, 442m): This bundled-tube skyscraper broke height records, becoming the tallest building in the world at the time.

- 1980s: Steel skyscrapers expanded globally, particularly in Asia, as Japan and China adopted steel for large-scale commercial and industrial projects.

- 1996: With explosive industrial growth, China became the world’s largest steel producer, fueling the rapid expansion of domestic infrastructure and high-rise construction.

By the late 20th century, steel was no longer limited to skyscrapers. It had become the backbone of global construction, supporting the development of stadiums, airports, bridges, and industrial complexes on an unprecedented scale.

1.4. The new era of steel structures (21st century)

In the 21st century, steel continues to define modern architecture. Cities across North America, Europe, Asia, the Middle East, and Australia embrace innovative steel technologies to achieve greater efficiency, sustainability, and design flexibility.

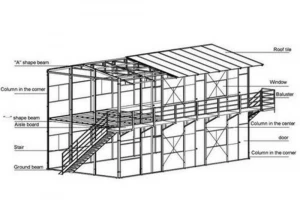

Expansion of lightweight steel housing

- Cold-formed lightweight steel has become essential for modular housing, prefabricated buildings, and earthquake-resistant homes in countries such as the United States, Canada, China, Japan, and Australia.

- Its recyclability, high strength-to-weight ratio, and fast assembly make it a preferred choice for modern residential projects.

- China’s rapid urbanization has accelerated the widespread adoption of lightweight steel housing, particularly in regions vulnerable to earthquakes and typhoons.

Growth of high-rise and super-tall structures

- Steel remains the dominant material for high-rise office towers, luxury apartments, and mega-infrastructure projects in cities such as New York, London, Dubai, Tokyo, and Shanghai.

- Hybrid steel-concrete composites are increasingly used to optimize load distribution, seismic performance, and cost efficiency.

- China has emerged as a leader in super-tall construction, with landmarks like the Canton Tower (600m) and the Shanghai Tower (632m, hybrid steel-core structure) demonstrating cutting-edge engineering.

Sustainable and green steel construction

- A global shift toward low-carbon steel production is reducing the environmental footprint of construction.

- China, the United States, and members of the European Union are investing in hydrogen-based “green steel” technologies to minimize emissions.

- Many modern projects integrate renewable energy systems, passive cooling, and smart building technologies to align with net-zero goals.

- Iconic examples include Beijing’s Bird’s Nest Stadium, Shanghai World Expo Pavilion, and Japan’s energy-efficient skyscrapers, which showcase how steel can deliver both sustainability and architectural excellence.

2. The technological development of steel structures

The history of steel structure development has always been driven by continuous breakthroughs in material innovation and construction technologies. These advancements enhanced strength, durability, and flexibility, allowing steel to meet the demands of increasingly complex architectural designs.

2.1. Steel material technologies

- 1856 - Mass production of steel: The Bessemer process transformed steelmaking by making production faster, cheaper, and scalable. This milestone enabled the use of steel in large quantities, opening the way for taller buildings, longer bridges, and vast industrial facilities.

- 1930 - Weathering steel (Corten steel): Developed to resist corrosion through a self-protective oxide layer, weathering steel became the preferred choice for outdoor structures such as bridges, towers, and industrial plants.

- 1980 - High-strength steel plates: Japan’s NKK Company introduced thermo-mechanical control processing (TMCP), creating steel plates with high strength and toughness while maintaining flexibility. This advancement allowed engineers to design taller skyscrapers and more durable infrastructure worldwide.

2.2. Construction technologies

- 19th century - Stability calculations: Leonhard Euler’s formula provided the first theoretical foundation for understanding structural stability. Later, the plastic design method of the 20th century allowed for more efficient, cost-effective, and flexible steel designs under complex load conditions.

- 1960s onwards - Computer-aided design: The adoption of CAD and finite element analysis revolutionized structural engineering. By simulating stress, loads, and behavior of steel components before construction, engineers could optimize designs, minimize errors, and accelerate project delivery.

- 1881 - Arc welding: The invention of electric arc welding replaced labor-intensive riveting, allowing steel components to be joined quickly, reliably, and with greater design flexibility.

- 1947 - High-strength bolts: The standardization of high-strength bolts improved connection efficiency, making assembly faster and disassembly easier. Bolted joints also enhanced load transfer capacity, strengthening the overall performance of steel structures.

3. Future trends in steel structure development

The future of steel structures is being shaped by innovation, sustainability, and digital transformation. Several key trends are expected to define the future of steel structures:

Structural innovation

- Space structures: Advanced systems such as grid shells and membrane structures are replacing traditional flat designs, maximizing efficiency and expanding creative freedom in architectural form.

- Light steel for high-rise buildings: Lightweight steel is increasingly used in multi-story residential projects, providing a practical response to urban density and growing housing demands.

Green building development

- Eco-friendly integration: The combination of steel with energy-efficient glass, solar roofs, and other sustainable materials helps reduce environmental impact.

- Low-carbon production: Modern methods such as modular construction and high-efficiency welding are minimizing carbon emissions during both steel manufacturing and assembly.

Composite structural trends

- Steel-concrete hybrids: Blending steel with concrete enhances stability, load capacity, and cost efficiency. Iconic examples include the Petronas Towers in Malaysia and the Jin Mao Tower in China..

Digitization and smart technology

- Building Information Modeling (BIM): Through 3D digital models, BIM streamlines design processes, reduces waste, and improves construction accuracy and efficiency.

- 3D printing: On-demand production of steel components is becoming a reality, lowering costs, enabling custom architectural designs, and minimizing material waste.

The history of steel structure development demonstrates how this material has shaped cities, industries, and societies for more than two centuries. Steel structures have proven their unmatched role in modern construction, shaping iconic landmarks such as the Eiffel Tower, the Empire State Building, as well as today’s energy-efficient skyscrapers and modular housing.

As a leading company in the field of steel structures, BMB Steel’s experts is ready to provide consultation and quotations for high-quality built-up steel tailored to each customer’s specific needs. We are committed to precise construction, on-time delivery, and helping clients achieve optimal investment efficiency.