Popular drawings of the textile industry factories in production

The textile industry is one of the key industries of Vietnam. Currently, the textile and garment industry not only meets domestic consumption needs but also exports to foreign markets such as Europe, America, Canada, Japan, etc. To meet consumer demand, the textile and garment industry factories are built more increasingly. Therefore, today BMB Steel would like to introduce to you the construction rules and design drawings of textile industry factories.

1. Standards to pay attention to when designing textile industrial factories

Whether it is a large industrial factory or a small industrial factory, a two-storey industrial factory or a one-storey industrial factory, the design of a textile industrial factory should also comply with the following design standards:

International design standards:

- AWS D1.1 Edition 2006.

- AISC. 2005 – American Institute of Steel Constructions.

- MBMA. 2002 – Metal Building System Manu.

- Quality Manual.

Vietnamese design standards:

- TCXDVN 338:2005. Steel structure – Design standard.

- TCVN 3223:1994. Electric welding rod for carbon steel and low steel.

- TCVN 1916:1995. Bolts, screws, studs, and nuts. Technical requirements.

Experimental test:

- TPI: Third Party Inspection.

- NDT: Non-Destructive Testing.

- MPI: Magnetic Particle Inspection.

2. Why should we build a textile industrial factory with pre-engineered steel frames?

Pre-engineered steel frame workshop is a factory-built from steel structures fabricated and assembled according to pre-specified technical drawings. Building a textile industrial factory with a pre-engineered steel frame brings the following advantages:

- Cost savings for investment owners: Compared with reinforced concrete factories, the cost of pre-engineered steel frame factories can be up to 35% lower per square meter (m2).

- A larger area: Textile industrial factories need a large space to store machines, so using pre-engineered steel frames will save more than 20% of the area compared to traditional construction methods.

- Fast construction process: Pre-engineered steel frame factory is built by assembling steel structures with bolts, so construction will happen faster with less machinery and equipment.

- Easily expand the factory scale when the investment owners need it.

3. Some crucial standards when designing textile industry factory drawings

The process of designing a drawing for the construction of a textile factory will have certain standards. Contractors, as well as investors, need to capture them so that the construction works smoothly and the factory is built in the best condition.

- Architects need to understand the size and structure of the workshop, architects need to design the premises based on the technological process provided by the investor, and arrange reasonable working areas to ensure the production output process is effective.

- Architects need to know the size parameters of specialized machines to be able to arrange reasonable space allocation and make the most of the area of the textile factory.

- Textile and garment industry factories need to be optimally designed in terms of area, spacious, airy, well-lit, and convenient for storing more machines when expanding the production of new products when necessary.

- Design production workshops are not too far apart and are convenient for moving materials between departments.

- The distance from the floor to the ceiling is in the range of 3 - 3.5m, the columns have a good bearing capacity, the floor is flat and has a good bearing capacity, the exit system, the ventilation, and air conditioning system need to be properly distributed, etc.

- In the process of designing factory drawings, architects will rely on the main type of manufactured goods to make specific requirements for specific standards for the factory in order to bring the best production efficiency and ensure safety for all labor and employees in the process of working.

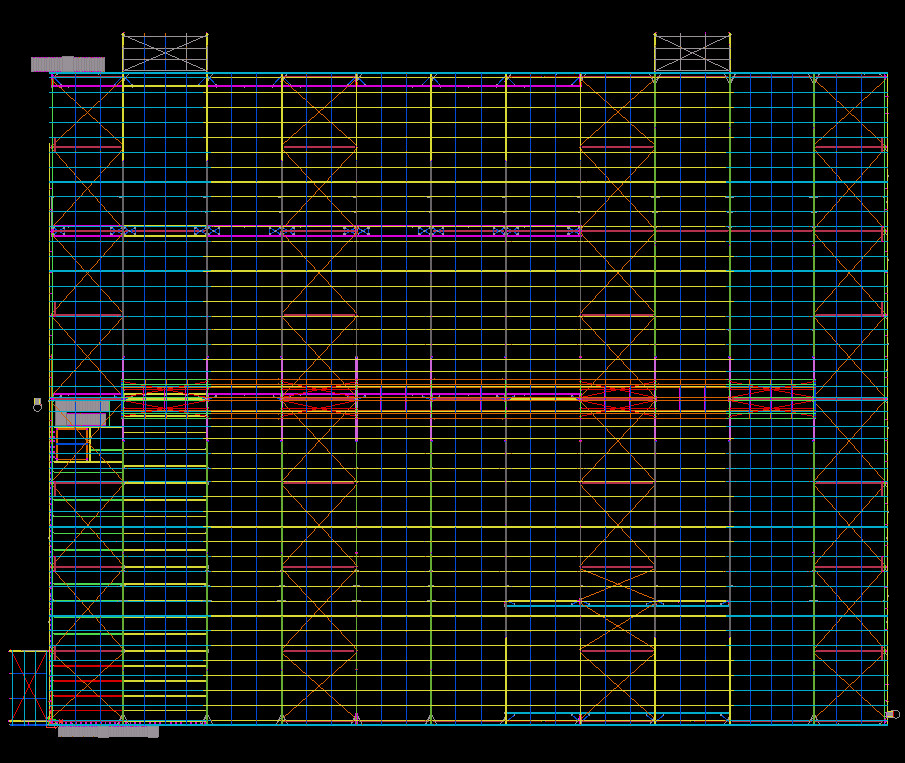

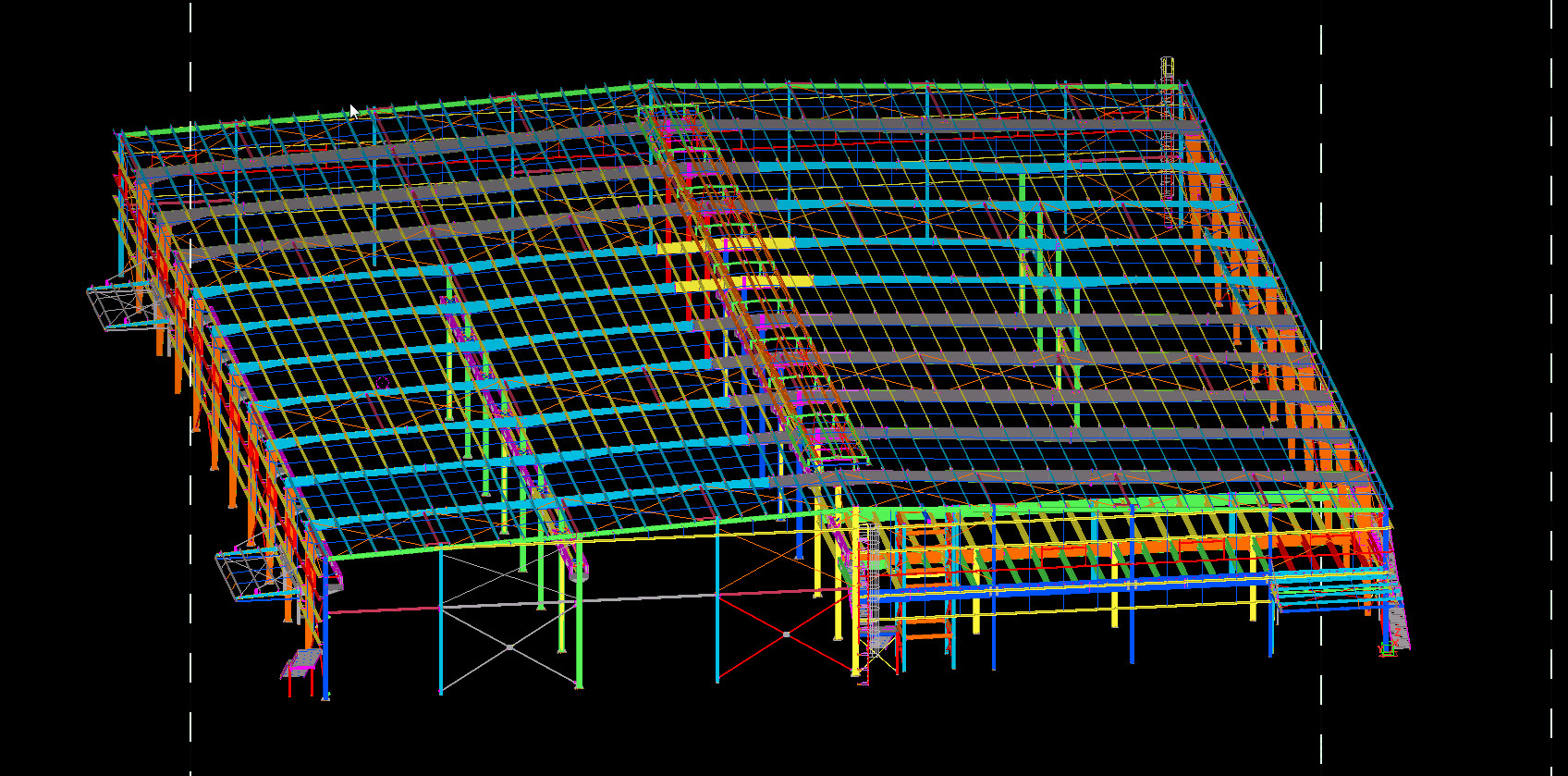

4. Drawings of textile industry factories

Below are pictures of some design drawings of textile industry factories that readers can refer to for their business. Investors can refer to the following templates to get more ideas for designing a unique and most suitable factory for their business.

Above is the information that we want to provide related to readers about the design of drawings of textile industry factories. Besides, at BMB Steel, we own a team of professional, experienced, and dedicated architects who will create great value for your projects. BMB Steel is committed to providing customers with works that are not only structurally perfect but also aesthetically pleasing. If you have any questions about the construction of a textile industrial factory, please contact us immediately for answers as soon as possible.