Popular drawings of mechanical industrial factory in construction

For the time being, along with the development of the economy, science, and technology, machines are increasingly replacing humans. This is a condition for the mechanical industry to develop - one of the critical factors of the mechanical industry in the factory. Today, BMB Steel will introduce to you the notes when building and designing mechanical industrial factory drawings.

1. The structure of the mechanical factory

The mechanical industry is a branch of science and technology based on the principles of designing, analyzing, manufacturing, and repairing machines and equipment for human life. Thanks to the mechanical industry, we have products such as cars, motorcycles, heating, cooling systems, etc.

To produce the above products, mechanical industrial factories were born. The mechanical industrial factory is the main production area for mechanical products, accounting for 40 - 60% of the workload of the whole manufacturing industrial factory. Mechanical industrial factories, which contain the most significant number of machines, machines with complex structures, many models, and great value, often account for a massive part of the enterprise's investment capital. Therefore, the construction of mechanical industrial factories is focused and has high design requirements.

A mechanical industrial workshop will include the following parts:

- Production department: including cutting machine storage, cooling space, processing product quality inspection area, etc.

- Auxiliary parts: including coil preparation area, cutting tool grinding area, semi-finished product storage, finished product storage, etc.

- Service department: including the company's office, common area, etc.

2. The process of designing mechanical industrial factories

Whether it is a large industrial factory, a small industrial factory, or an industrial manufacturing factory, the design process of a mechanical industrial factory will include the following steps:

- Design and test the process of operating machinery to create a mechanical product.

- Determine the total number of employees expected to operate in the factory.

- Determine the number of machines needed and calculate the total energy required to operate the machines for the production process.

- Determine the need for materials and tools for transportation and repair activities.

- Identify labor needs.

- Determine the scale of the workshop.

- The layout of the suitable mechanical workshop.

- Determine the factory structure and install lifting equipment.

- Identify metrics that characterize production capacity and efficiency.

3. Some notes when designing mechanical industrial factories

Choosing the suitable building materials, the type of material used to build the mechanical factory must be durable, easy to maintain, clean, and disinfect when necessary.

Structures surrounding the workshop, such as walls and partitions, must be designed with smooth surfaces and made of impervious materials. The floor is designed to be quickly drained, avoiding dynamic water damage to the finished product.

Doors and windows must have a smooth surface, are made of waterproof materials, and must be easy to clean when necessary.

Ensure principles when designing mechanical processing lines:

- Ensure the appropriate material utilization factor Kv, Kv=mct/mph ( mct is the part weight, mph is the workpiece weight).

- Ensure machining accuracy.

- Ensure good machining productivity according to the relationship between machining capacity Q and machining time for each tc. Q=1/tc.

- Reduce the time factor Kt=t0 /t tc (t0: is the base time, ttc: is the machining time of each piece).

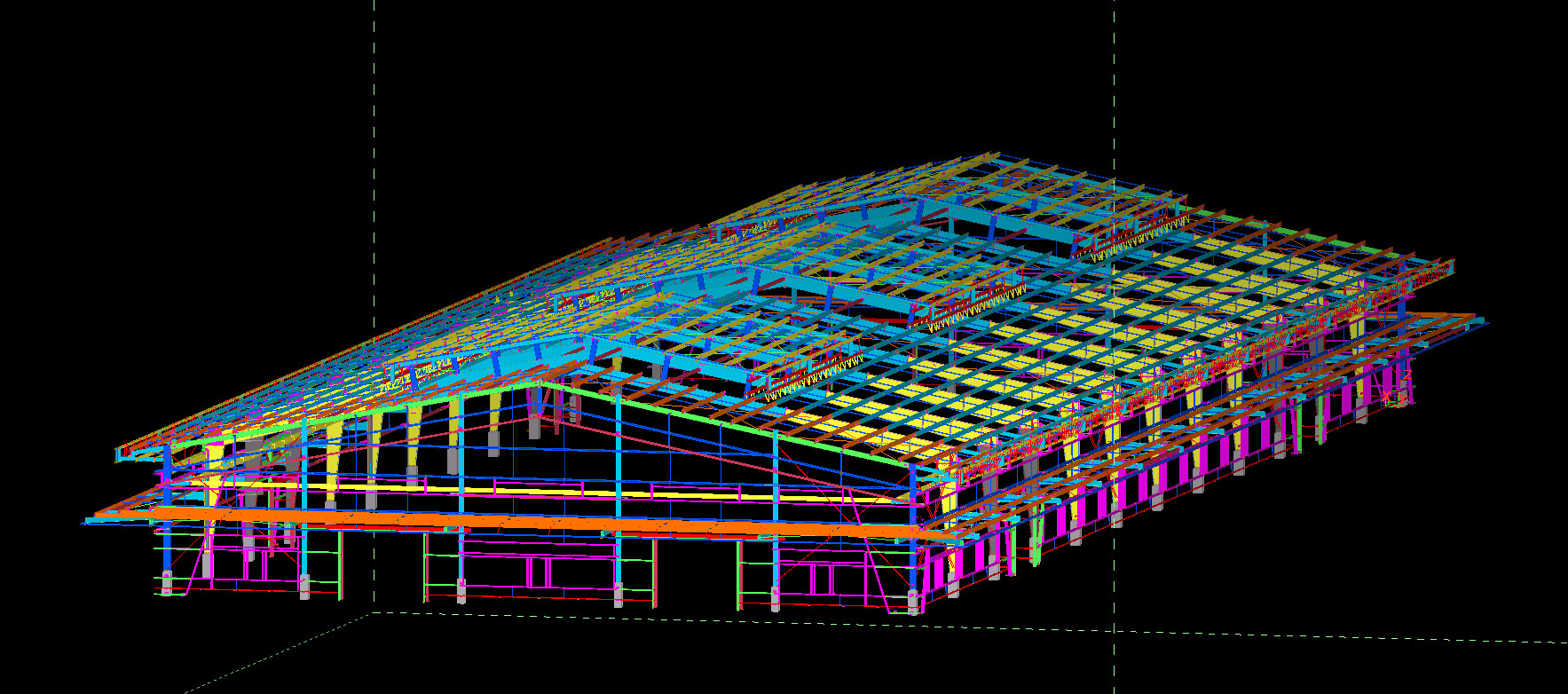

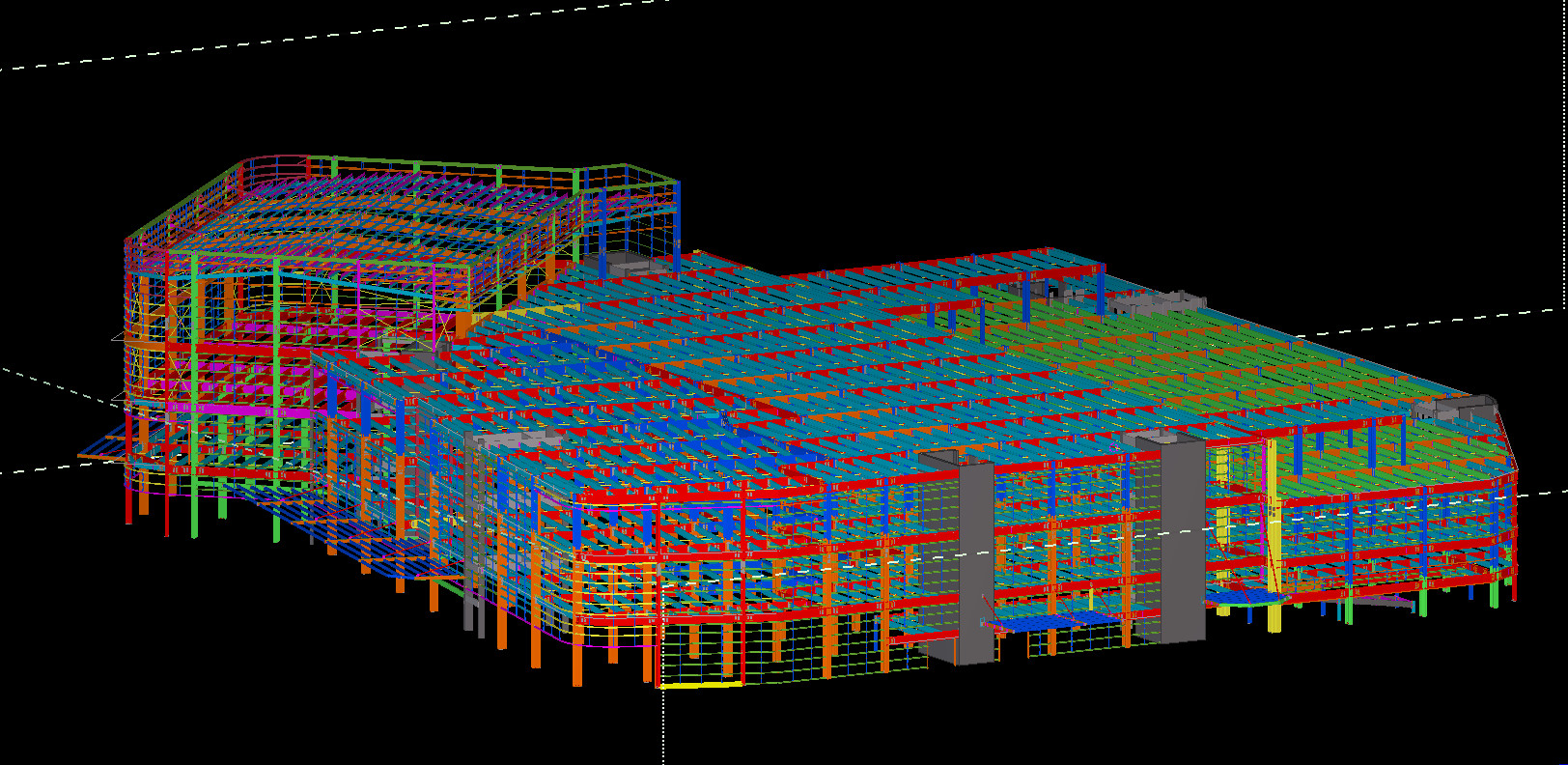

4. Some drawings of industrial mechanical workshops

Below are pictures of some mechanical industrial factory drawings that BMB Steel has made. The drawings fully show the three areas of a typical industrial mechanical workshop: the production area, the auxiliary area, and the service and living area.

We would like to provide readers with some pictures of popular mechanical industrial factory models today. Building a mechanical industrial factory is a significant factor in the success of a mechanical enterprise. A good factory and meeting the technical requirements will help the production process and protect the finished product go more smoothly.

BMB Steel is a company that designs and builds factories and workshops with more than 18 years of experience. Regardless of whether it is a small or large industrial factory, the company will implement the optimal design and suit the requirements of the investment owners, bringing customers satisfaction.