Some practical tips for your warehouse design

Currently, no matter how large they are, all enterprises own their warehouses used for producing, storing, and maintaining commodities. How can we take all the advantages of our warehouses and operate them best? Look at BMB Steel’s article below to find out about 11 practical tips for designing warehouses.

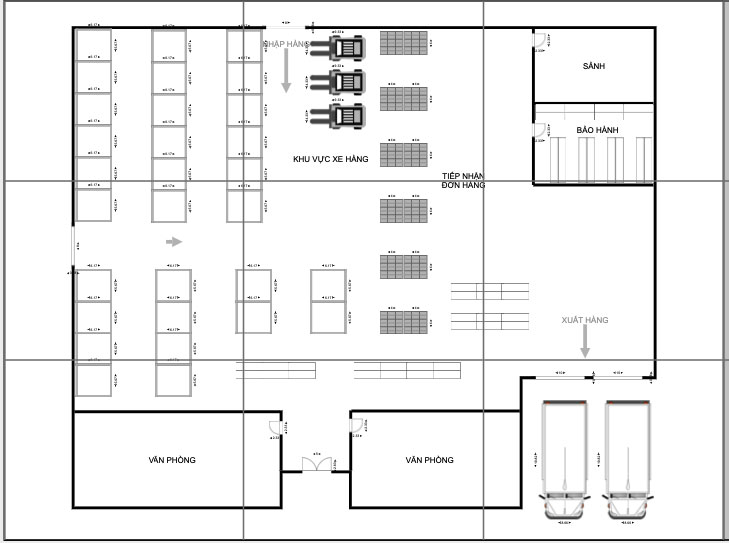

1. Design a warehouse diagram

We need to draw a detailed warehouse diagram in order to show an overview of it as well as specific corners to arrange goods and operate the business. Based on the warehouse diagram, we can make the best plan for arranging aisles and items in the way that is most convenient for everyone.

Generally, enterprise owners hire professional architects to design the most entire and most detailed diagram for massive and spacious warehouses with various areas and procedures.

Steps to draw warehouse diagram:

- 1st step: Prepare a warehouse floor plan which includes detailed information about the exact sizes of all areas and procedures within the warehouse.

- 2nd step: Select the warehouse diagram method from the below list: Microsoft Excel method, online software method, or architects and professions method.

- 3rd step: Arrange positions of specific areas within the warehouse. Determine the main areas (Operation area, Storage area, Blank Space), then subdivide these areas into smaller sections. During the design process, question yourself in order to have a thorough look at the warehouse, such as “What procedures will be done?”, “Where will they happen?”, “How much time does it take for the shipment to be delivered to the warehouse?” and so on.

2. Stimulate order process

Develop a visual stimulation of actual orders in order to see whether everything is strictly stored, operated, and issued or not. This process helps owners find problems and solutions to address them. Estimate the number of workers focusing on the area to improve work efficiency. Stimulating, analyzing, observing, and improving helps enterprises create the most effective and appropriate warehouse plan.

3. Make a plan to optimize warehouse space

Based on the warehouse’s total area, owners need to make detailed plans for particular areas. For example, storage’s total area, packing’s total area, production’s total area, and so on.

We can do this on paper by making accurate estimations and arranging everything in appropriate order and positions.

4. Choose appropriate equipment

Generally, enterprises make mistakes in choosing equipment they do not want to pay much for. This is not true. Equipment actually makes the working process become more effective and smooth.

You - enterprises should consider and choose suitable equipment that meets 3-A requirements “Abundant - Appropriate - Attractive”. You should buy whatever is in need and convenient for your warehouse operation, then arrange it in the correct positions.

5. Keep track of the process and result

After you finish the warehouse diagram, you need to check its effectiveness. This checking helps you thoroughly understand minor problems within the warehouse. Then, make some adjustments to create the most effective and suitable plan.

If you have not constructed any warehouses, you can make a list of potential problems, use stimulation to picture the warehouse, and make opinions and judgments about it.

6. Select the appropriate method to store goods

Enterprise has two options for warehouse design:

- Random storage: Store the goods in different positions around the warehouse so that you can find everything easily anywhere. However, it takes time for staff to go around the warehouse to find them.

- Batch storage: Divide goods into different batches and store them in specific areas. This method helps staff easily find the things they need, but it is unsuitable for significant commodities.

Enterprises should carefully consider storage before designing warehouse architecture.

7. Select warehouse layouts

Selecting warehouse layout types is significantly essential. Enterprises can choose from the following list:

- U-shaped layout: A type of warehouse with a U-shaped bottom makes transportation faster and more convenient.

- I-shaped layout: The type of warehouse has a simple design, with one end used for receiving goods, the middle used for storage, and the other used for delivering goods.

- L-shaped layout: Type of warehouse with two same-size L-legs with functions similar to an I-shaped layout.

8. Select a trustworthy warehouse designer

When selecting designers and architects for your construction buildings, you need to consider their experience, reputation, and quality. This helps provide you with the most effective designs.

Above are all the practical tips BMB Steel listed, hoping enterprises to develop their most effective plan when designing warehouses. If you have any further questions, please feel free to contact us.