Discover interesting facts about span in factory construction

The factory span plays a crucial role in construction, affecting various factors such as safety, operational efficiency, maintenance costs, etc. Through this article, BMB Steel will provide a comprehensive overview of interesting facts about span in factory construction.

1. What is the span in factory construction

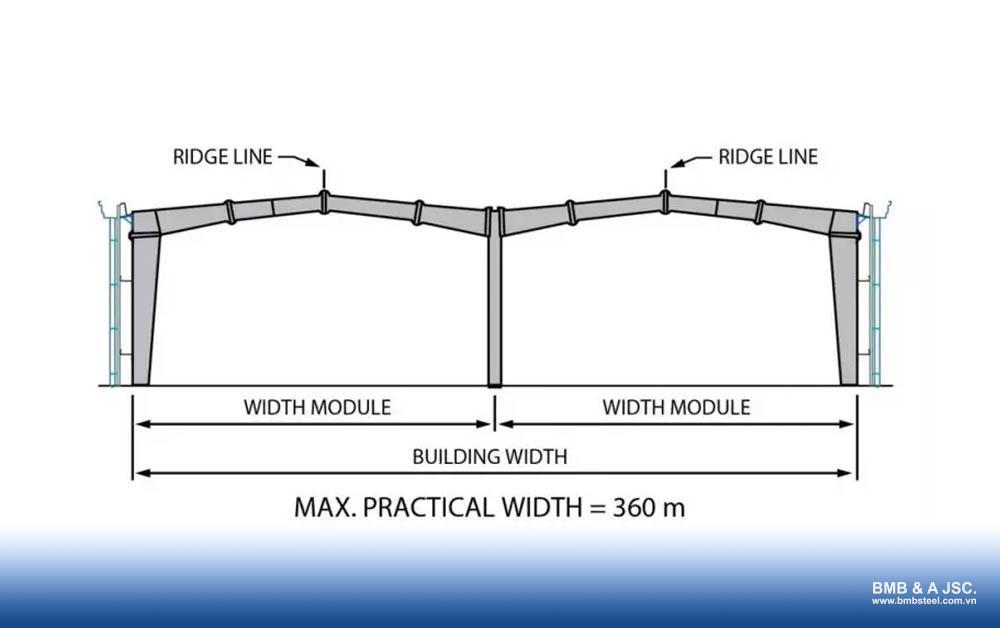

The span in factory construction refers to the width of the factory, measured from the edge of one column to the edge of another. Depending on the size of the land and usage needs, the span will vary, such as 25m, 30m, 50m, etc.

The span determines the distance between two columns and affects the choice of lifting equipment, machinery, rails, pipelines, materials, etc. The wider the span, the higher the operation, maintenance, and repair costs.

2. Other types of span in the construction

In addition to the span in factory construction, there are many other types of spans related to infrastructure projects. Each type of span has its significance in ensuring the stability and safety of the structure.

2.1. Culvert span

This is the largest horizontal distance inside a pipe, playing a decisive role in the ventilation efficiency of the culvert system. It is a key factor that helps the underground culvert system and urban water drainage operate effectively.

2.2. Bridge span

This refers to the length of a bridge span, which directly affects the stability and durability of the bridge. The longer the bridge span, the stronger the structure and materials need to be to ensure load-bearing capacity.

2.3. Calculated span of bridge span structure

This is the distance between the centerlines of the supports of a bridge span, used to calculate and design the bridge structure, ensuring the load-bearing capacity and stability of the entire project.

2.4. Water drainage span

This is the distance between the inner edges of the two bridge abutments, after subtracting the width of the piers, ensuring sufficient space for effective water drainage. This is especially important in areas with large amounts of water or during the rainy season.

This is the width of the bridge span allocated for vessels to pass through. The design of the navigational span must suit the size of the vessels and the volume of water traffic in that area, ensuring safe passage for ships and boats.

3. Some terms in the factory construction

3.1. Column spacing

This refers to the distance between two adjacent columns along the length of the factory. It is an important factor that influences the division of space and the structure of the building.

3.2. Factory height

This is the height of the factory, measured from the base of the side column to the roof's edge. Each factory has a different height, depending on the design and technical requirements of the project.

3.3. Roof slope

This is the incline of the roof, expressed as a percentage (%). The slope can range from 5% to 30%, depending on the design of each project. An ideal slope of 10% ensures good water drainage and effective waterproofing.

3.4. Floor load

This refers to the load-bearing capacity of the factory floor, including the weight of goods, machinery and other equipment placed inside the factory. The floor must be carefully calculated to meet long-term load-bearing requirements.

3.5. Roof load

This includes the load of the roof panels, insulation, ventilation equipment, ensuring that the roof is durable enough to support these loads without affecting the overall structure of the factory.

3.6. Overhead crane

These are lifting devices used to move goods inside the factory. Overhead cranes help lift, lower, transport machinery and goods quickly, saving time and labor.

3.7. Rafter

A rafter is a structural component that connects different parts of the roof and supports the roof. Rafteres are typically triangular and made from steel or wood, helping to bear the load and distribute the weight of the roof to both sides.

3.8. Roof framing

This is a structural system made up of trusses and horizontal beams that create a solid frame to support the entire roof.

4. How to determine factory span

4.1. Determine the factory width

This is the first important factor to consider, as the width of the factory directly affects the span. The width determines the distance between the load-bearing columns, which influences the structural design.

4.2. Determine the load requirements

It is essential to understand the load requirements, including dynamic loads (equipment, workers, etc.) and static loads (roof, walls, etc.). This helps in determining the durability of structural components and the appropriate spacing between structural elements.

4.3. Choose appropriate materials

Construction materials (steel, concrete, etc.) greatly affect the span. Steel is often preferred for projects with large spans due to its flexibility and high load-bearing capacity.

4.4. Use standard span calculation formulas

Apply technical formulas to accurately calculate the span. For example, the method of calculating the ratio between span and depth helps estimate the beam depth for each specific span.

4.5. Comply with construction standards

All calculations and designs must comply with building regulations, including maximum span limits and technical requirements related to the structure.

4.6. Consider environmental factors

It is important to account for factors such as wind, earthquakes, temperature fluctuations. These factors can affect the durability and stability of the span during the factory's operation.

5. Applications of diverse spans in construction

5.1. Factories, industrial plants

The span is an important factor in the design of factories, especially in large industrial areas. With a large span, the space inside the factory is optimized for the easy installation and operation of various machinery. These structures often use durable steel frames, capable of achieving spans from 30m to 40m.

5.2. Airports, train stations, squares

For expansive projects like airports, train stations, a large span creates an open space that is uninterrupted by supporting columns. These structures often have spans exceeding 100m, ensuring flexibility and effective operation.

5.3. Apartment, high-rise buildings

The high-rise building’s span enhances the load-bearing capacity and stability of the structure. For buildings over 15 stories, steel structures are often preferred to create open spaces, reduce the number of columns, and improve construction efficiency.

5.4. Road, railway bridges

Road and railway bridges use steel structures with large spans to ensure stability and high load-bearing capacity. Suspension bridges with spans exceeding 1000m are prime examples of applying spans in important transportation infrastructure.

The span in factory construction is critical to the design and construction of buildings. By determining the correct span, you can make informed design choices that enhance safety and functionality. Optimizing the span ensures that structures can accommodate machinery and withstand environmental factors

To achieve an optimized factory span design, contact BMB Steel immediately for consultation and support from leading experts in the field of pre-engineered steel buildings and steel structures.