Latest comparison of design standards for steel structures

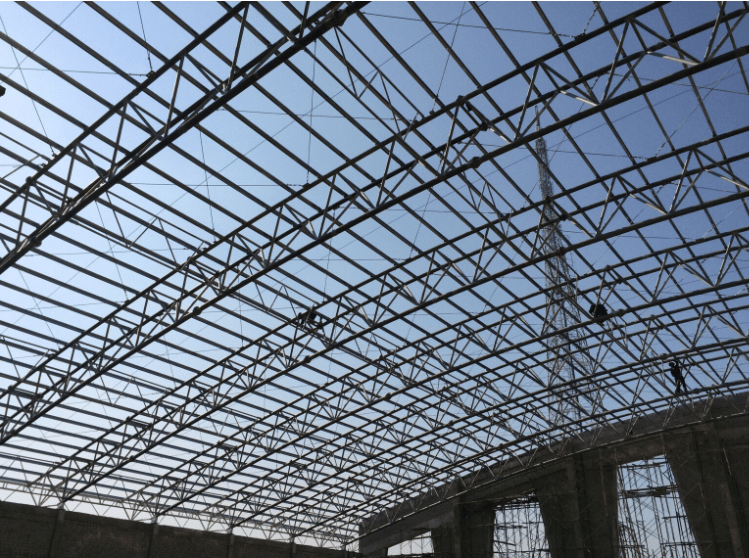

Along with the growing industry, it is compulsory for constructions to meet the quality standards to ensure their safety and longevity. For a project, each category will have different evaluation standards. In the article below, BMB Steel will show you an overview of the latest comparisons of design standards for steel structure.

1. Features of design standard qualifying steel structure

1.1 Characteristics of standards for steel structures in Vietnam

Vietnamese standards for steel structures TCVN 5575:2012 originated from Russia. For Vietnamese standards, all construction procedures must be applied with the method and the SF (safety factor) including:

- Safety factor of load

- Safety factor of materials provided for the construction process

- Safety factor in the working environment, called Occupational Safety and Health (OSH)

Accordingly, Vietnam standards for steel structures focus on the stiffness and steel structures must not be deformed excessively.

In terms of calculated intensity, for TCVN, the calculated intensity is calculated by the formula: Standard intensity/ Material safety factor.

In terms of the assumed load, it is calculated with the formula: Standard load * load certainty factor.

According to Vietnam steel design standards, no. 2737:1995 is used as the assumed load for steel structures. The speed of wind load is measured in 3 seconds, in a 20-year period.

The wind pressure coefficient in Vietnam is calculated by wind pressure, not by speed. It is determined by the results of pressure measurement in the wind tunnel model, so it can be applied to cubic objects.

1.2 Đặc điểm tiêu chuẩn thiết kế thép theo tiêu chuẩn Mỹ AISC 89/ASD.

Apart from the design standard in Vietnam, the American steel structure design standard is a method widely applied by contractors. American standard features apply 2 calculation methods:

- Method 1: According to Allowable Strength Design (ASD) and load factor: Accordingly, the strain must not exceed the allowable stress = yield stress* (0.6 -> 0.67)

- Method 2: According to the Load and Resistance Factor Design (LRFD): The load is multiplied by the factor 1.2->1.6; bearing coefficient is multiplied by 0.75->0.9; The main stress is the yield strength.

The relationship of Ft, Fy, Fb: When in tension, the value of allowable stress Ft = 0.6Fy (Fy: yield strength of steel). In compression = Fy x longitudinal flex coefficient. The limit value of bending structure (Fb) value from 0.6-0.67Fy.

Internal force values: M,N,Q caused by standard load, no overload factor. However, the formula for determining internal force has a combination of loads.

Section: The assumed area for US standards is divided into 3 parts: solid section, thin section, and non-solid section. Calculating a solid cross-sectional area will certainly use up the allowable efficiency of the material. For the calculation of the non-solid cross-sectional area, the allowable stress of the material should be reduced. Similar to the thin section, it must be further reduced.

1.3 Features of steel design standards based on European standards Eurocode 3

European steel structures standards are calculated with limit standards (bearing capacity and usage limit). The limit stress is calculated using multiple factors to multiply by the yield strength.

Section: Divided into several grades based on thinness (width/thickness). Thicker level 1,2 is charged with higher stress. Level 3.4 is thinner so it is easy to lose the local stability. It is similar to the Vietnamese Standard & American Standard according to LRFD. Thus, the section is divided into 4 types: solid section, non-solid section, plastic section, and thin section.

Load: based on BS 6399, need to consider floor load, wind load and snow load.

Notes of the wind load:

- Wind load pressure is calculated from wind speed by considering the terrain, type of building, etc

- The aerodynamic coefficient of the wind load must include the negative pressure inside the building. The most dangerous coefficient value must be chosen for calculation. BS 6399 uses the average wind speed in one hour, in a 50-year period; Parallelly, the British standard also uses CP3 using wind speed measured in 3 seconds, in a 50-year period.

Allowable displacement: calculated as the maximum value due to the used load (live load) regardless of the overload factor. Greater deformation is allowed according to TCVN. For example: ceiling support beam L/360 (according to TCVN L/400); auxiliary beam L/200 (TCVN L/240); and only take the calculated live load, do not take the whole as TCVN.

Safety factor: According to BS 6399, each different load uses a different safety factor: For example: The factor of safety (HSAT) of the dead load is 1.4 (TCVN is 1.2); active load is 1.6 (TCVN is 1.2 or 1.3); wind load is 1.4 (TCVN is 1.2). In addition, the safety factor for the material is taken as 1 since it has been adjusted during the calculation of the material strength. According to TCVN, the safety factor of materials is 1.05 to 1.1 depending on the type of steel. Besides, BS does not have safety factors on building function, working coefficient of structure, while TCVN does.

If the HSATs of BS's are compared with that of TCVN, VN's HSAT is smaller than that of BS. Thus, with the same steel material and bearing the same nominal load, the structure calculated according to TCVN requires less material.

2. Design load standards in some countries

The design load of each country has a certain standard. Here are design load standards in some typical countries:

- Vietnam: TCVN 2737:1995: Loads and impacts, design standards.

- USA: MBMA 2002; UBC 97; IBC 2006;

- UK: BS 6399: Part 2: 1997: Load for Building: Part 2: Code of practice for wind loads; BS 6399: Part1: 1984: Design loading for buildings: Part 1: Code of practice for dead and Imposed loads.

- Europe: EN 1991-1-4:2005 A1: Action on structure.

- Australia: AS/NZS 1170.1:2002: Australia/New Zealand Standard for dead, live and other loads; AS/NZS 1170.2:2011: Australia/New Zealand standard for wind loads

The design load is determined based on the structure's external factors such as the construction site’s influences, the impacts from the weather, etc. Although each country has its own standards, it is recommended to apply the most fundamental principles to ensure the safety for the construction as well as anticipate errors and dangers to occur.

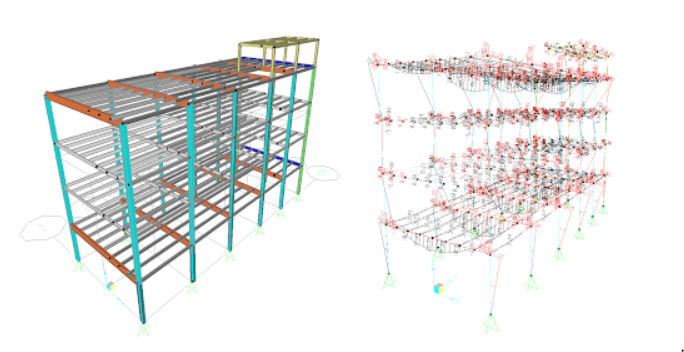

3. Comparisons of current steel structure design evaluation standards

Current evaluation standards of the steel structure design depend on the steel structure design standards of each country. From them, we are able to use which criteria to apply for evaluation.

- Vietnam bases on No. 5575:2012: Steel structures – Design standards for safety.

- US bases on No. AISC-89: The American Institute of Steel Construction - Inc emphasizes on elasticity and the way the material works.

- UK: BS 5950: Part 1: 1990: British Standard: Structure use of Steelwork in Building: British Standard.

- Europe: EN 1993-1-1: European Standard – Steel structures design: This standard is widely used in construction projects but it insists on factors such as proper investigation, safety levels.

- Australia: AS 4100-1998: Australian Standard for Steel Structures; AS 4600:1996: Australia/New Zealand Standard: Copper clad steel structure.

In general, in order to evaluate whether a steel structure design is guaranteed or not, it is essential to evaluate the ability, the safety standards, and the load capacity of the structure before and during the design process of steel structures

Currently, steel structure design is not only based on the standards of each country but also plays a crucial role in prefabricated buildings—a type of construction that uses steel structures to optimize time and costs. Prefabricated buildings must meet load-bearing requirements and comply with international standards such as TCVN 5575:2012 in Vietnam or EN1993-1-1 in Europe to ensure safety and durability. The selection of appropriate steel structure design standards is a key factor in the construction of prefabricated steel buildings, ensuring quality and cost optimization for investors.

4. Cautions when applying steel structure design standards

Investors need to choose appropriate standards to steel structure fabrication to achieve precision, quality and ensure safety for the project:

- Finance: Invest in the project with a budget suitable for your affordability.

- The building environment: Ensure to apply other standards

- Carefully survey the plan and the construction environment: For construction, it is vital to synchronize all factors.

- Do not let one standard combine with another. If that happens, the project will no longer be unified and safe.

In the article above, BMB Steel has shared with you the comparisons of the latest steel structure design standards. Hopefully with this information, the owners and contractors can choose the suitable standards for their projects.