Occupational safety in fabricating and erecting the pre-engineered building

It is necessary to ensure occupational safety in fabricating and erecting pre-engineered steel buildings so that construction has high quality and does not negatively affect workers working on the construction.

1. Factors that cause a lack of occupational safety in fabricating and erecting the pre-engineered steel building

Recently, pre-engineered steel buildings are known for their stability and long durability, not inferior compared to traditional buildings. However, the construction process might include potential risks because of loose association. The steel structures are carefully designed, and each little detail matches with each other perfectly. Any mistake in erecting can cause serious consequences.

In addition, steel structure that is connected tightly can cause deformation because of delivery or weather factors such as wind and storm. This most often applies to frameworks that are just being built because of their low durability and stability. This includes potential risks that can damage workers’ safety and the quality of the construction.

Regarding the human factor, being reckless and careless during the construction process can lead to serious situations. Just a little mistake of a crane driver, such as a small collision with a newly produced framework, can cause it to deviate, deform and significantly fall down. During the steel structure fabrication process, workers have to work under harsh weather conditions, at high altitudes, and at hot temperatures, which leads to a reduction in concentration and an increase in negligence.

One of the major reasons is the erection process does not meet strict regulations on occupational safety in an erection.

2. Ensuring occupational safety in fabricating and erecting pre-engineered steel buildings

Workers must make sure that they are in good health conditions and are equipped with full sets of protective wear during the whole production process.

- Crane drivers must maintain alertness and concentration and avoid being distracted while controlling the vehicles, ensuring the safety of humans and construction buildings.

- The working team must take a rest when the weather is terrible, such as heavy rain, wind, and storm.

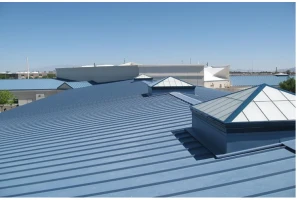

- To ensure the safety of the pre-engineered steel buildings, firstly, workers need to install rigidly braced bays at the gable. They must also include temporary braces during erection as well. Then, they need to connect roof purlins and wall purlins together with rafter frames using brace cables. There must be enough of all these components: rafters, roof braces, wall braces, strut purlins, and temporary brace cables connecting rafters and anchors.

- After checking the finished brace bays, the control team needs to check and examine the exact level of the framework, testing height, deviation, defection, etc). Then, workers continue to connect other frames to the main brace frame. The best thing is to connect the whole frame, but it is easier to begin with 50 percent of each section’s purlins, then finish the whole frame.

3. Occupation safety in fabricating and erecting pre-engineered steel buildings in BMB Steel

We always strictly follow regulations on occupational safety, giving priority to human factors. BMB always emphasizes all details in each step of the whole procedure, from fabricating to erecting, ensuring safety for everyone who participates in the project.

In our production factory, machine maintenance is required all the time. We also focus on technology innovation and the safety of machine systems. BMB Steel also takes pride in protecting the workers’ environment, health and safety during the working process by equipping full sets of protective wear according to mechanical regulations. During the welding and drilling process, we equip our workers with protective wear, such as protective goggles and masks.

All workers and staff are well trained in health protection as well as the required knowledge. Safety is not only for each individual but also for surrounding people. At BMB Steel, occupational safety is associated with working culture and is the company's long-term goal and mission. Occupation safety is also an important factor that the company uses in branding as well as earning trust from customers and partners.

BMB Steel takes pride in receiving safety awards in fabricating and erecting pre fabricated buildings in both domestic and foreign areas, affirming its position among steel structure building companies.

The erection process includes many potential risks, which suggests that construction companies emphasize occupational safety in fabricating and erecting pre-engineered steel buildings. We hope that the information provided is useful. Visit our website at BMB Steel for more related information.