The construction and erection process of pre-engineered steel buildings meets 2025 standards

For factory and pre-engineered building (PEB) constructions, investment owners need to understand the implementation process to control and closely monitor the project’s progress. What is the standard pre-engineered steel building construction process? In this article below, BMB Steel will answer this question.

1. Construction and erection process

Understanding the construction and installation process for a construction project is one of the most important factors for any investor or individual who wants to carry out a successful construction project. This decision not only affects the quality, schedule, and budget of the project but also ensures labor safety and compliance with legal regulations. Here is the entire process:

1.1 Pre-engineered building design drawing

From the very beginning, drawings of pre-engineered buildings need to be designed because this is an integral factor in showing the general structure and the necessary details in the project. From there, contractors will provide suitable solutions for construction and design with the most optimal plan.

Drawings of the pre-engineered building need to demonstrate the following factors:

- Plans of the building structures

- The specifics of the work with clear figures, dimensions, quantities

- Ground plan layout, the layout of components

- Manage drawings

1.2 Process and manufacture pre-engineered building (PEB) components

With accurate measurement data, layout drawings, and detailed design, the next step in the pre-engineered factory construction is processing the material components. It is necessary to adhere to the principles and data to produce components with correct requirements and measurements.

The component processing steps include cutting, processing the gusset plate, assembling, welding, and assembling the gusset plate. Finally, clean the structure’s surface, then paint layers such as anti-rust, anti-fire, etc. The materials used are all made of steel, corrugated iron, etc., which are capable of insulating heat and are resistant to the effects of climate and weather.

1.3 Erecting pre-engineered building components

When assembling pre-engineered steel building components to complete the work, builders need to have methods to protect labor safety. There should be supporting machinery to support and put the materials together.

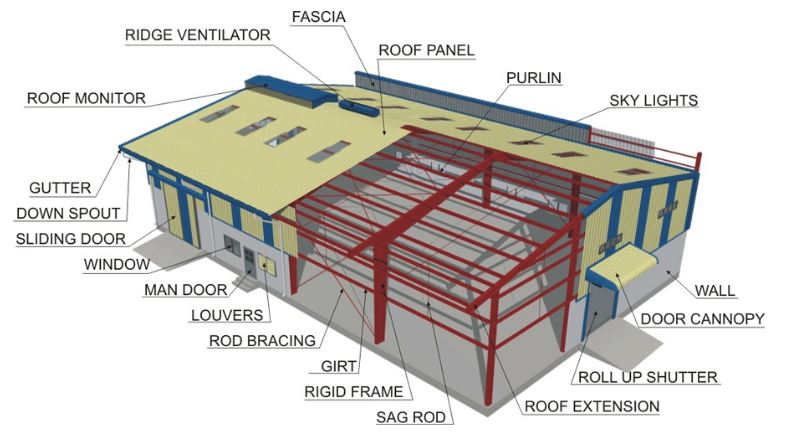

1.3.1 Construction of the mainframe

First, assemble the mainframe (including installation of columns, truss beams, rafter frames, and purlins). During the installation process, you should pay attention to the standards according to the drawings. In this process, the support of equipment and techniques is essential. When aligning, you have to be sure that the columns reach a certain height and straightness. Thus, the new frame will ensure solidity to bear the load of the whole house.

See more: The steel structure fabrication process meets the most detailed standards

1.3.2 Construction of the cover and surrounding

The cover of the work includes the roof, the wall, the gutter, etc. When installing the corrugated iron sheets, you must use sliding pipes to pull the corrugated iron sheet on the roof, fixed by iron hooks. Right from the first installation of panels, it must be aligned to close the entire roof to achieve high aesthetics and good quality.

1.4 Inspecting and handing over works

The final stage is to inspect the entire project to ensure quality and compliance with standards. Problems need to be discovered and resolved before handing over the project to the investor.

Maintaining documentation and establishing warranties is the final step in ensuring that the project will be maintained and maintained effectively after completion.

Each step in this process plays an important role in building a successful project that meets the investor's requirements. This process requires precision, high technique, and good schedule management to ensure that the construction project is carried out with quality and efficiency.

BMB Steel introduces you to the necessary information about the standard prefabricated house construction and erection process. You should clearly understand the above process steps to be able to build a quality and highly aesthetic project.

See more: Steel structure introduction

2. Be sure to choose a quality construction and installation company

2.1 Determine project needs

Before you start looking for a construction company, you need to determine the needs of the construction project. This includes determining the type of project, scale, goals, budget, and time needed for completion. Knowing your specific needs will help you easily choose the right company.

2.2 Research and select companies

After determining your needs, you need to do research to choose the most suitable construction and installation company. This includes searching and listing reputable companies in the construction sector.

It is necessary to set important criteria such as experience, quality of previously completed projects, after-sales service, and ability to comply with schedule and budget to conduct consultation in choosing an erection company.

2.3 Check experience and achievements

Once you've found a list of potential companies, evaluate their experience and track record. Check out the projects they have worked on in the past to see the quality and professionalism of the company.

Try to learn about the companies' experience and track record by reading reviews and feedback from previous customers. This can help you evaluate their ability to complete your project successfully.

Provide specific criteria for evaluation, such as ability to comply with schedule, quality of work, and ability to solve problems.

Deciding to choose the right construction and installation company is important to ensure your construction project is carried out with quality and efficiency. Thorough research and determining your specific needs will help you make the right choice and be confident in your decision.

3. Solutions to common problems in construction and installation

Below is a detailed description of solutions to common problems during construction and installation:

3.1 Budget issues

To solve budget-related problems, you need to take measures to save resources and budget for the project:

- Set a detailed budget and stick to it strictly.

- Consider choosing the best value materials and equipment to reduce costs while maintaining quality.

- Conduct contract negotiations with suppliers to obtain preferential prices and discounts.

- Monitor and manage costs and profit margins closely to avoid wasting resources and going over budget.

3.2 Issues of time and progress

To manage time and project progress effectively, you can take the following measures:

- Plan detailed construction progress and strictly follow it.

- Use project management software to track and update progress regularly.

- Identify priority and high-priority tasks to ensure that important tasks are not late.

- Develop contingency plans to deal with unexpected problems and avoid schedule delays.

3.3 Quality and safety issues

To ensure quality and safety during construction, you need to apply the following measures:

- Ensure that all workers and employees comply with occupational safety rules and regulations.

- Use high-quality materials and equipment to ensure the safety and durability of the project.

- Carry out periodic quality checks and final quality checks before handing over the project.

- Implement environmental protection measures if necessary and comply with environmental protection regulations.

These solutions can help you solve common construction problems effectively, ensuring that your project will be completed on schedule, within budget and with quality and safety at the highest.

To learn more about steel structures and receive detailed pricing, visit BMB Steel – the leading provider of steel structure solutions in Vietnam.