The steel structure fabrication process meets the most detailed standards

- 1. What is Steel Structure Fabrication?

- 2. Applications of Steel Structure Fabrication

- 3. Popular Methods in Steel Structure Fabrication

- 4. Choosing the Right Steel Materials

- 5. Steel Fabrication Process for Pre-Engineered Factories

- 6. Steel Fabrication Cost in 2024

- 7. Quality Standards and Inspection in Steel Fabrication

- 8. Tips for Choosing a Reliable Steel Fabrication Service

Steel structure fabrication plays a vital role in constructing solid and durable pre-engineered buildings. This process includes several important stages. Refer to the article by BMB Steel to gain useful insights.

1. What is Steel Structure Fabrication?

Steel structure fabrication is the process of transforming steel materials into structures of specific shapes and sizes using common methods such as cutting, welding, bending, and straightening. This process goes beyond simply assembling and shaping steel; it involves advanced techniques and technologies to create robust, durable, and safe constructions.

2. Applications of Steel Structure Fabrication

Steel structure fabrication is widely used in various fields, including:

- Construction: For creating building frameworks like factories, pre-engineered steel buildings, high-rise structures, and bridges.

- Industry: Used in fabricating industrial structures such as machinery and equipment.

- Transportation: Creating structures for transportation, such as ships, vehicles, and related infrastructures.

3. Popular Methods in Steel Structure Fabrication

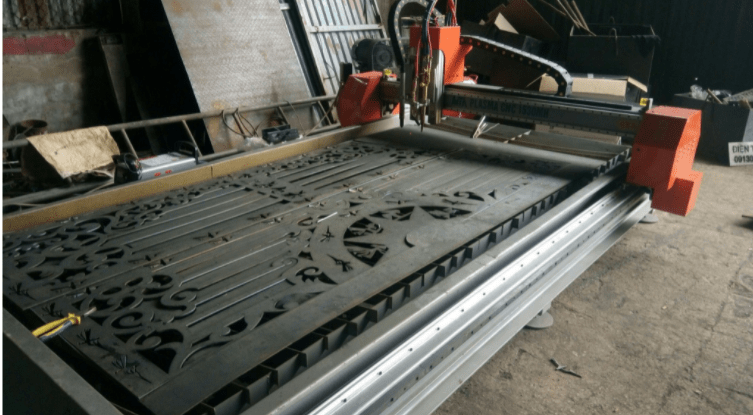

Steel Cutting: Utilizing machines to cut steel into desired shapes and sizes through methods like metal blade cutting, plasma cutting, and laser cutting.

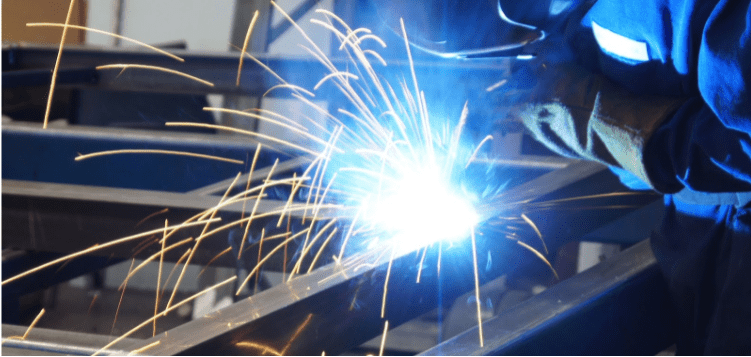

Steel Welding: Heating and connecting steel plates using methods such as arc welding, acetylene welding, or laser welding.

Steel Bending: Applying force to bend steel into specific shapes using bending machines or manual and electric tools.

Steel Straightening: Reshaping steel using tools like straightening machines, manual straightening tools, or electric devices.

4. Choosing the Right Steel Materials

Selecting the appropriate steel material is crucial to ensure the safety and performance of the project. Here are some common steel types along with their pros and cons:

4.1 Carbon Steel

- Advantages: Low cost, easy to fabricate and weld, and good hardness.

- Disadvantages: Prone to corrosion if not coated or painted; unsuitable for highly corrosive environments.

4.2 Stainless Steel

- Advantages: High corrosion resistance, excellent mechanical strength, aesthetic appeal, and easy cleaning.

- Disadvantages: Higher cost and sensitivity to high temperatures.

4.3 Alloy Steel

- Advantages: High hardness, durability, and good mechanical properties at high temperatures.

- Disadvantages: Higher cost and stringent production quality control requirements.

4.4 Corten Steel

- Advantages: Natural corrosion resistance, ideal for outdoor projects, aesthetically pleasing with unique color.

- Disadvantages: Higher cost and strict production quality requirements.

4.5 Galvanized Steel

- Advantages: Good corrosion resistance due to zinc coating, low maintenance, suitable for outdoor applications.

- Disadvantages: Higher cost than regular carbon steel and less aesthetic flexibility.

5. Steel Fabrication Process for Pre-Engineered Factories

The steel fabrication process for pre-engineered factory buildings includes:

- Requirement Assessment: Analyze steel structure requirements and prepare detailed fabrication drawings.

- Material Preparation: Ensure the availability of all necessary materials and tools.

- Steel Cutting: Cut steel sheets into individual blanks based on the design.

- Drilling and Connecting: Drill holes and connect components using bolts.

- Temporary Assembly: Align and shape steel components before temporary assembly.

- Structural Welding: Weld components to create a unified steel structure.

- Adjustment: Align any misaligned steel parts.

- Cutting and Attaching Base Plates: Trim the ends of structures and attach base plates.

- Surface Treatment: Clean the steel structure's surface and prepare it for painting.

- Protective Coating: Apply three layers of paint (anti-corrosion primer and two topcoats).

- Quality Inspection: Check all components for compliance with international standards before storage and transportation.

6. Steel Fabrication Cost in 2024

The cost of steel structure fabrication ranges from 1,000,000 to 2,000,000 VND/m², depending on factors such as:

- Type of Structure: Each type requires different technical and material specifications.

- Size and Complexity: Larger and more complex designs incur higher costs.

- Fabrication Methods: Costs vary based on cutting, welding, and bending techniques.

- Fabrication Unit: Established providers with advanced technology and expertise may charge more due to quality and capability.

7. Quality Standards and Inspection in Steel Fabrication

7.1 International Standards

- ISO 9001: Ensures compliance in production and quality control.

- ISO 3834: Covers welding standards for steel production and construction.

- EN 1090: Specifies requirements for steel and alloy structure design, production, and inspection.

7.2 Inspection and Certification

- Product Inspection: Ensuring structures meet technical and design standards.

- Welding Quality Check: Assessing weld quality for structural integrity.

- Material Inspection: Verifying the quality of steel materials used.

- Product Certification: Certified by reputable inspection organizations.

Periodic inspections throughout the production process ensure compliance with standards and regulations, guaranteeing safe and durable steel structures.

8. Tips for Choosing a Reliable Steel Fabrication Service

Selecting the right partner for steel structure fabrication is critical for project success. Here’s why it matters:

- Ensuring Quality: Experienced partners deliver products that meet all technical standards, reducing production errors.

- Cost Optimization: Reliable services optimize material use and manage budgets effectively.

- Compliance with Standards: Professional services ensure international standards and safety requirements are met.

- Time Management: Efficient partners adhere to timelines, avoiding project delays.

- Professional Guidance: Expert advice enhances design efficiency and cost-effectiveness.

Thorough research and consultation with experts can help you select a trustworthy fabrication partner, ensuring high-quality and cost-efficient steel structures.

Above, BMB Steel has fully shared important information about steel structure fabrication. Hope your business will understand more and complete the project successfully. Please follow BMB Steel's articles to update more useful construction information.

Read more: