Common Steel Structure Manufacturing Equipment in 2022

What equipment must involve in the steel structure production process? To ensure the quality of pre-engineered steel buildings, factories have had to invest a lot in machinery and equipment. In this article, BMB Steel will introduce you to the types of equipment used to produce steel structures.

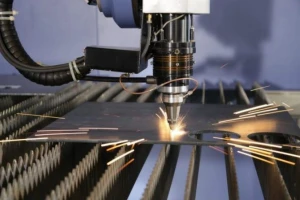

1. Plasma Cutting Machine

This machine uses cut steel by taking advantage of the exceedingly high plasma heat. It requires a three-phase power source with a suitable voltage to create a high temperature for the steel to melt. The cutting lines create quickly, cleanly, and without roughness. This device can cut straight lines, curves, and even perpendicular lines by reducing the cutting speed. Because the temperature is very high during construction, which can be dangerous, the safety factor for the person in charge is always a top priority.

2. Circular saw machine

The circular saw can cut steel materials with various angles such as 90, 60, and 45 degrees. The control screen in front of the body allows the user to adjust the angle and observe the cut easily. The saw blade runs in a particular direction, cutting quickly and accurately. It can cut a variety of materials.

>>> Read more: Prefabricated buildings have become a construction trend

3. Steel cutting machines

The steel cutter has an electric motor and a geared circular blade. The saw blade rotates at high speed for fast and precise cutting. The disadvantage of this type of machine is that it cannot cut many materials simultaneously.

4. Steel structure welding machine

There are many types of welding machines on the market today; below are the specialized types used in the production of pre-engineered steel buildings:

4.1 TIG Welding Machine

The advantage of this type of welding machine is that it is very versatile and can be used on most metal materials from thin to thick, creating clean and neat welds. Compared with MIG welding machines, this method has slower progress, which leads to time-consuming problems and production costs.

Using the TIG welding machine effectively requires skilled workers. However, thanks to the slower speed, it is easier to control the welding process better and create strong, accurate, and aesthetically pleasing welds.

4.2 MIG, MAG welding machine

Unlike TIG welding machines, MIG machines often use more extensive and thicker materials. This method uses the heat generated by the combustion of the generated electrode to form an arc that fills the weld. The higher the operator's skill, the less likely the welds will be bent and warped.

MIG and MAG can take into account as one type of machine. The only difference between these two machines is that the core and the gas stream formed from the puddle are inert gas (MIG) or activated gas (MAG). These air currents have the effect of cleaning the weld and pushing the air out to avoid the phenomenon of air holes.

As mentioned above, this welding machine is more efficient than the TIG welding machine when producing steel structure fabrication. However, in terms of certainty and cleanliness of the weld, the TIG series prevails.

4.3 Beam welding machine

This device is many times larger in size than the above welding machines. With a sturdy frame structure shaped like a gate, this machine creates stable and strong significant welds by an automatic operating mechanism with a clamping design and welding under a layer of solder by two high-power welding torches on either side.

This solder layer is also automatically supplied and recovered by the system. The machine's gears must ensure smooth and precise frame movements. Welding speed can also adjust via the machine's inverter control. In addition, another advantage of the beam welding machine is the self-selecting mechanism; the machine will automatically adjust the welding torch to create the most aesthetic and accurate welds.

Because it is automatic, the beam welding machine can work continuously, bringing higher productivity than conventional manual welding methods when manufacturing steel structures.

5. Hydraulic press machine

This type of machine creates explicitly desired shapes and contours for steel. The bending force of the machine can adjust to a great extent, which can bend even large area materials, so it is widely used in the production of steel structures. The steel plates are shaped, and angled under pressure from the top down or bottom up.

The entire bending blade will move on the steel plate to create even or custom straight bending lines. With this equipment, we can turn the steel plates into different shapes according to the intended use.

6. Shot blasting machine

The shot blasting machine cleans, polishes, and hardens the steel structure. Similar to a sandblasting machine, this machine will spray spherical abrasive particles (balls) onto the steel. These particles can be iron or silicon carbide to help clean and polish the surface. In addition, the shot blasting also has the effect of increasing the adhesion of the paint coating on the steel to prevent the steel from rusting.

Above are some of the equipment used in the production of steel structures that we have shared. Hopefully, you have gained useful information. If you want to learn more about structural steel and related issues, come to BMB Steel to get the necessary information.