What is purlin? Types and applications of purlins in construction

What is purlin? This is a common question for those just starting out in the construction industry. In this article, BMB Steel will help you understand the concept of purlins, their outstanding advantages, the popular types of purlins and their applications.

What is purlin?

What is purlin? A purlin is a horizontal structural member typically made from steel or wood, used to support the roof or floor structure. They play an important role in maintaining stability and distributing the load from the roof or floor to the beams and columns of the structure. Purlins not only ensure the durability of the structure but also contribute to its overall aesthetics.

In terms of material, purlins are divided into two main types: wooden purlins and steel purlins. In traditional architecture, wooden purlins were widely used, but due to their poor fire resistance, vulnerability to termites, and easy decay, they have become less common. Today, steel purlins have replaced traditional options, becoming the most popular choice due to their high durability and superior resistance to termites and fire.

Advantages of purlins in construction

- High durability: Steel purlins are far more durable than traditional materials like wood, resisting decay and withstanding harsh weather and environmental conditions.

- Lightweight: Despite having excellent load-bearing capacity, purlins are relatively lightweight, helping to reduce the overall load on the structure.

- Easy installation: Steel purlins are precision-manufactured to standard dimensions, making them easy to transport and install without much effort.

- High aesthetics: The product has a smooth surface, resists deformation and rust, and maintains its appearance for a long time.

- Cost savings: With good load-bearing capacity and long life, purlins help reduce maintenance and replacement costs during use.

Applications of purlins in construction

So, what is a purlin, and how are they applied in construction? In practice, purlins are widely used in many types of projects, pre engineered steel building, particularly in factories, prefabricated buildings, warehouses, and civil structures. Specifically:

- Roof Support Frame: Purlins are used as a support system for roof sheets and can also be used to suspend equipment mounted on the roof, such as fans, lights, electrical systems, etc.

- Wall Support Frame: Purlins serve as a support system for wall sheets, door systems, louvers, and more.

- Primary Structural Frame: For small-scale structures, purlins can be used to replace columns and trusses to optimize project costs.

Common types of purlins today

After learning what a purlin is, let’s explore the common types available today. Currently, there are two popular types of purlins on the market: C purlins and Z purlins. Each type has distinct characteristics suitable for specific construction requirements.

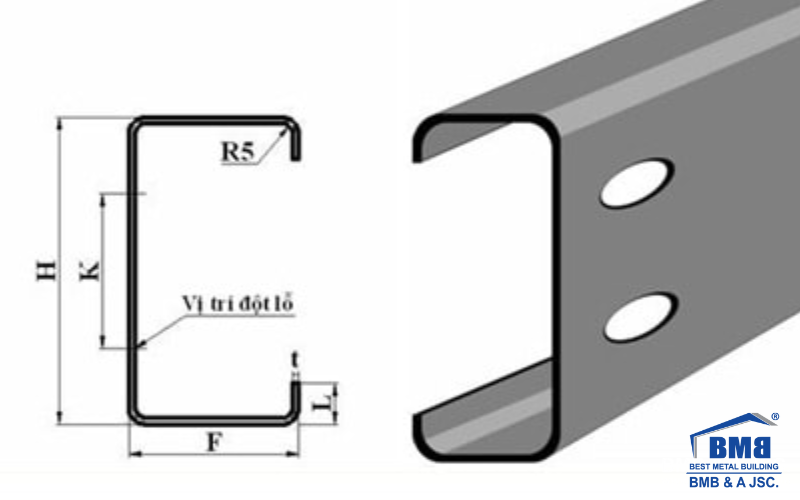

C Purlins

C purlins are named based on their cross-sectional shape, which resembles the letter "C." They are typically used in small to medium-sized projects, such as residential buildings, warehouses, and small prefabricated structures. Key features of C purlins include:

- Good load-bearing capacity: With a special structure, C purlins can effectively distribute loads evenly across the entire structure.

- Easy fabrication and installation: C purlins can be easily cut to size, saving time and installation costs.

Z Purlins

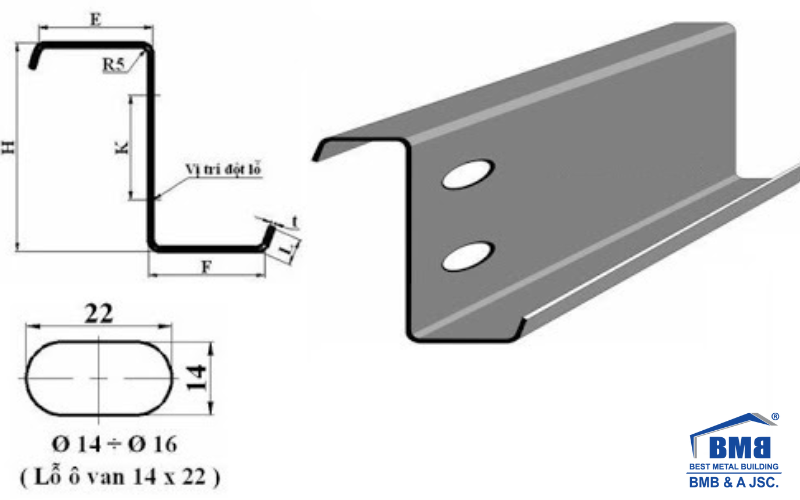

Z purlins have a cross-sectional shape resembling the letter "Z" and are commonly used in large-scale projects, such as factories and steel-frame buildings. Key features of Z purlins include:

- High load-bearing capacity: Z purlins can handle larger loads compared to C purlins, making them ideal for projects requiring robust structures.

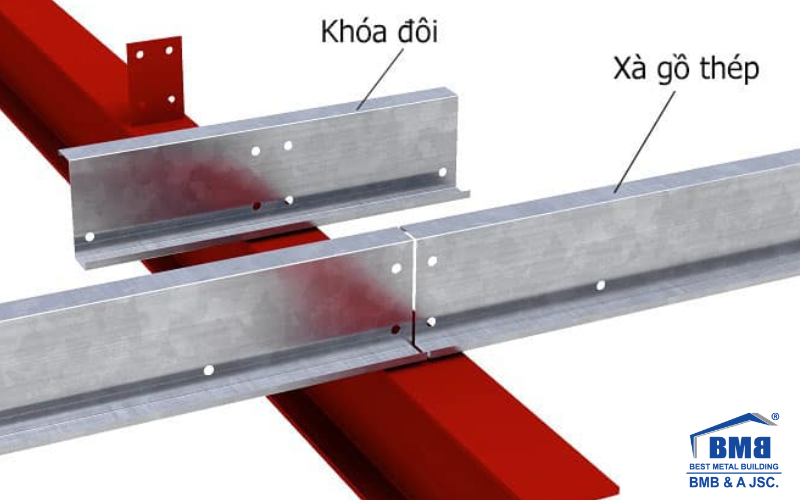

- Flexible installation: Z purlins can be easily extended by connecting them without welding, making them ideal for larger frameworks.

Considerations for designing purlins in construction

The design of purlins plays an important role in ensuring the durability and safety of a project. Here are some key points to consider when designing purlins:

- Material and thickness: It is advisable to choose galvanized steel purlins to increase rust resistance. The thickness of the purlins should also be appropriate for the load-bearing requirements of the project.

- Roof weight: If using heavy roofing materials, more purlins should be arranged and tightly fastened to ensure safety. Lighter roofing materials reduce overall weight and save costs.

- Ideal distance between wall purlins and roof purlins: The distance should be between 4 to 6 feet (1.2 to 1.8 meters) to ensure stability.

- Purlin ratio: The length-to-depth ratio of purlins should be 1/32 to ensure proper load-bearing capacity with the chosen wall or roof materials.

- Suspension rods and roof peak: Suspension rods should be installed in balance at opposite positions, and the roof peak must be tightly connected along the length of the roof to increase lateral stiffness.

Which supplier should you choose for purlin design and construction today?

With the rapid development of the construction industry, many companies offer purlin design and construction services. However, to ensure quality, you should choose reputable companies with years of experience. Key criteria to consider include:

- Experience and capability: The construction company should have extensive experience in the field of construction and purlin installation.

- Material quality: The supplier should guarantee the quality of the purlins, particularly their rust resistance and durability.

- Reasonable price: Compare prices among different companies to ensure you get a reasonable rate without compromising on quality.

In conclusion, "What is purlin?" is a key question in construction, where purlins play a crucial role in supporting roofs and walls. If you are looking for an effective construction solution, please contact BMB Steel immediately for advice and to choose the most suitable purlin.