Alloy steel: Key features & applications in construction

Alloy steel is an indispensable material thanks to its exceptional durability, high load-bearing capacity, corrosion resistance, and versatile applications in various harsh environments. However, not everyone fully understands this special type of steel, including its composition, properties, classification, and practical applications. In the following sections, BMB Steel will provide you with clear and accurate answers.

1. What is alloy steel?

Alloy steel is a type of steel composed of iron and carbon, with the addition of other chemical elements such as manganese, chromium, nickel, molybdenum, vanadium, etc. The proportion of these elements ranges from 1% to 50% of the total mass of the mixture, depending on the technical requirements of each specific application. This combination aims to improve the physical and chemical properties of the steel, enabling the material to perform better under harsh working conditions.

Some outstanding characteristics of alloy steel include oxidation resistance, increased strength, improved ductility, impact resistance, and adaptability to high temperatures. Depending on the added element, alloy steel will have different properties:

- Manganese: helps control the cooling rate during heat treatment, reducing the risk of cracking when hardening steel.

- Chromium: enhances wear resistance, produces stainless steel when the chromium content exceeds 11%, improves hardness and strength.

- Molybdenum: increases hardness and ductility at high temperatures, improves corrosion resistance, and enhances heat treatment efficiency.

- Vanadium: boosts hardness, wear and impact resistance, controls grain size to improve mechanical properties.

Read more: Drawings of pre-engineered steel buildings trending in 2021

2. Classification of alloy steel

Alloy steel can be classified based on the alloying element content and its intended practical applications.

Classification by alloy content:

- Low alloy steel: This type of steel contains a total alloying element content of less than 5%. Low alloy steel is widely used in various industries thanks to its balance between performance and production cost. Typical examples include: 20Cr, 30CrMo.

- Medium alloy steel: Contains about 5% to 10% alloying elements. Compared to low alloy steel, medium alloy steel offers higher strength and better wear resistance, making it suitable for components that require high load capacity and long service life. A common example is 40CrNiMo.

- High alloy steel: This group contains more than 10% alloying elements. These steels are often used in harsh environments or for applications with special requirements for corrosion and heat resistance. Stainless steels such as grades 304 and 316 are typical representatives, thanks to their high chromium and nickel content, which significantly enhances oxidation resistance.

Classification by intended use:

- Structural alloy steel: Mainly used in manufacturing machine parts, beams, factory frames, and other load-bearing structures. This type of steel must ensure good ductility, high mechanical strength, and excellent load capacity. Examples include: 20Mn2, 40Cr.

- Tool alloy steel: Suitable for manufacturing cutting tools, molds, equipment that require high hardness and long-lasting sharpness. Examples include: SKD11, SKH51.

- Heat-resistant alloy steel: Designed to maintain mechanical properties at high temperatures without deformation under extreme heat conditions. Common applications include furnace components, turbine engines. Examples include: 304, 310S.

- Stainless steel: A high-alloy steel containing more than 10.5% chromium, notable for its excellent corrosion resistance. Stainless steel is widely used in the food, pharmaceutical, interior decoration, and chemical industries due to its high aesthetic appeal.

3. Outstanding features of alloy steel

Mechanical properties:

One of the most notable characteristics of alloy steel is its superior mechanical strength, especially after undergoing heat treatment processes such as quenching and tempering. Alloy steel demonstrates significantly higher hardness and load-bearing capacity compared to carbon steel.

Heat resistance:

Alloy steel can maintain stable mechanical properties at high temperatures, exceeding 200°C. To achieve this characteristic, alloy steel is alloyed with special elements such as molybdenum, vanadium, chromium in high concentrations during production.

Physical and chemical properties:

Some types of stainless alloy steel offer exceptional corrosion resistance. In addition, alloy steel exhibits stable thermal expansion when the temperature changes. Depending on the specific alloy composition, it can also enhance other properties such as thermal conductivity, ductility, and machinability, etc.

4. Standard designations of alloy steel

Alloy steel is produced in many different grades, so the designation systems are also diverse and vary by country or region.

Meaning of letters and numbers in alloy steel designations:

- First number: Indicates the carbon content, usually written as the percentage multiplied by 100. For example, “20” in “20C” corresponds to 0.2% carbon.

- Element symbols: Represent the main alloying elements such as Cr, Ni, Mo, etc., sometimes followed by a number if the element’s concentration is high.

- X or S: Often found in stainless steels, used to indicate steels with high chromium content.

Below are some common designation systems according to international standards:

Designation according to the Vietnamese standard

According to the Vietnamese standard, steel is named based on its main chemical composition and intended use.

Examples:

- 20Cr: Alloy steel with about 0.2% carbon and additional chromium (Cr).

- 40CrNiMo: Alloy steel with about 0.4% carbon, combined with chromium (Cr), nickel (Ni), and molybdenum (Mo), commonly used for parts requiring high strength.

Designation according to the Japanese Industrial Standard (JIS)

In the JIS (Japan Industrial Standards) system, designations often start with the letter “S” (Steel), followed by characters indicating application or alloy composition.

Examples:

- SCM440: Cr-Mo alloy steel (chromium-molybdenum) with about 0.4% carbon.

- SKD11: Tool alloy steel containing chromium, commonly used in mold and cutting tool manufacturing.

Designation according to the US standard (ASTM, AISI, SAE)

Organizations such as ASTM, AISI, or SAE use a numerical system to classify alloy steel based on alloy composition and steel groups.

Examples:

- 4140: Medium alloy steel with about 0.4% carbon, combined with chromium and molybdenum.

- 4340: Medium alloy steel with about 0.4% carbon, combined with chromium, nickel, and molybdenum.

Stainless steels also have distinctive codes:

- 304: Common stainless steel containing chromium and nickel, offering good corrosion resistance.

- 316: Higher grade than 304, with added molybdenum for improved corrosion resistance in chloride or harsh chemical environments.

Designation according to the European standard (EN)

The EN (European Norm) system typically uses numbers and chemical symbols to describe composition.

Examples:

- 42CrMo4: Steel with about 0.42% carbon, containing chromium and molybdenum, often used in high-strength applications.

- X5CrNi18-10: Stainless steel containing about 18% chromium and 10% nickel, equivalent to stainless steel 304.

Designation according to the Russian standard (ГОСТ)

In the Russian standard (GOST), designations often use Cyrillic letters representing alloy elements, combined with numbers indicating carbon content.

Examples:

- 30ХГСА: Steel with about 0.3% carbon, along with chromium (Х), manganese (Г), and silicon (С).

- 12Х18Н10Т: Stainless steel with 18% chromium (Х), 10% nickel (Н), and titanium (Т), used in highly corrosive environments.

5. Applications of alloy steel in the construction industry

In modern construction, alloy steel is increasingly used thanks to its superior mechanical properties, durability, and resistance to environmental impacts. Due to its flexibility in alloy composition, this material is suitable for various types of projects. Some common applications include:

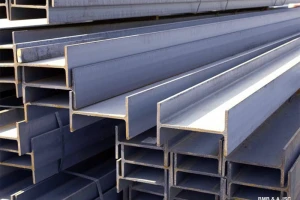

- High-strength steel structures: Alloy steel is an ideal choice for projects that require high load-bearing capacity, long-term durability, especially in projects such as bridges, high-rise buildings, industrial structures (factories, warehouses, storage facilities, etc.) thanks to its excellent wear resistance, strong mechanical strength, ability to withstand environmental factors such as temperature, humidity, or chemicals, etc.

- Load-bearing columns and beams: In components that carry heavy loads such as columns, beams, and foundations, using alloy steel brings significant benefits. This type of steel not only provides high load-bearing capacity but also offers effective corrosion resistance.

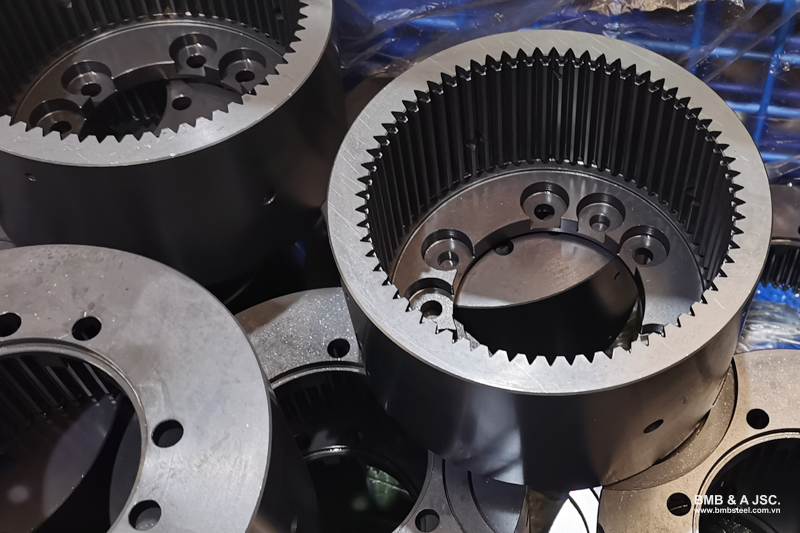

In addition, alloy steel is also widely applied in many other industries such as mechanical engineering, machinery manufacturing, automotive, aerospace, oil and gas, energy, military, shipbuilding, etc.

6. Distinguishing between alloy steel and carbon steel

In the materials industry, alloy steel and carbon steel are two common types of steel, but they differ significantly in composition, properties, and applications. Below is a detailed comparison table to help you easily distinguish between them:

|

Criteria |

Alloy steel |

Carbon steel |

|

Definition |

A type of steel containing a high proportion of alloying elements other than iron and carbon. |

A type of steel whose main components are iron and carbon, with carbon content below 2% and very little or no other alloying elements. |

|

Features |

The properties of alloy steel vary depending on the proportion and type of alloying elements added. This allows the steel to meet different technical requirements such as hardness, strength, heat resistance, etc. |

Properties mainly depend on carbon content: low carbon increases ductility, high carbon increases strength and load-bearing capacity but reduces weldability, ductility, and melting temperature. |

|

Corrosion resistance |

High corrosion resistance, especially in alloy steel containing Cr, Ni. |

Poor corrosion resistance, easily oxidized. |

|

Strength |

High strength, excellent load-bearing capacity. |

Lower strength compared to alloy steel. |

|

Melting point |

Higher. |

Lower. |

|

Cost |

Higher production cost due to the proportion of alloying elements. |

Cheaper, especially low-carbon steel, which is widely used in manufacturing. |

Alloy steel is not only a highly applicable material in construction but also plays an essential role in many other industries thanks to its durability, corrosion resistance, and superior mechanical properties. If you are looking for a high-quality steel structure solution that meets international standards, BMB Steel is a trusted partner to accompany you in every project.