Top 10 small and cost-saving pre-engineered factories for warehouse

- 1. Advantages when building a small pre-engineered factory

- 2. Top 10 popular small pre-engineered factory models

- 2.1. Factory model with a bright transparent roof

- 2.2. Factory model with many airy windows

- 2.3. Factory model with steel frame and corrugated iron roof

- 2.4. Factory model with wall combined with corrugated iron roof

- 2.5. Factory model with high steel frame and roof

- 2.6. Small pre-engineered factory model

- 2.7. Simple small factory model 500m2

- 2.8. Gorgeous factory model 1,000m2

- 2.9. Small factory model 1,200m2

- 2.10. Model of a small factory made of corrugated iron

- 3. Benefits of constructing prefabricated steel frame factories

Currently, small pre-engineered factories are gradually becoming very prevalent in many businesses of diverse designs, beautiful structures, and effective cost savings. Below, look at the top 10 small and cost-saving pre-engineered factories that BMB Steel most commonly constructs.

1. Advantages when building a small pre-engineered factory

- Space saving: Use for many different purposes and needs without wasting space such as warehouse, garage or processing workshop, production. Thanks to this feature, businesses can easily change the factory type and reposition parts of the production process when needed.

- Cost savings: Save on rental costs and restoration costs because the cost of renovating the factory is proportional to the area.

2. Top 10 popular small pre-engineered factory models

2.1. Factory model with a bright transparent roof

This factory model is designed widely at the door to facilitate transportation, making it easy to catch natural sunlight and save a lot of electricity. In addition, the roof design is transparent to create spaciousness for the factory as well as contribute to making use of sunlight.

The application of a transparent roof factory will help save costs because compared to using reinforced concrete, the cost of building a factory is many times lower. An outstanding feature is its high durability; the walls and the corrugated iron roof are designed to bond securely and firmly to every detail. In addition, the time to build this pre engineered steel building is relatively fast and convenient for many businesses.

2.2. Factory model with many airy windows

This type of factory is designed with many windows around the 4 walls of the factory with transparent corrugated iron panels to create spaciousness and ventilation and simultaneously receive natural sunlight most effectively. Above is the skylight to maintain light absorption and optimize energy saving for businesses.

This factory model creates a spacious and comfortable working environment for employees. Although it needs an appropriate investment, the construction cost is still quite low, which is suitable for many businesses.

2.3. Factory model with steel frame and corrugated iron roof

The 2-layer anti-rust painted steel frame structure is assembled from steel structures linked by screws and welds with high bearing capacity. The top is a corrugated iron roof with a fairly simple structure compared to other materials, so it is very compact. Significantly, this factory model can easily change when businesses want to upgrade or refurbish.

This is a small pre-engineered factory that is deployed by many businesses today because:

- Saving construction costs, a steel frame structure with a corrugated iron roof is lighter than a tile roof. Besides, the maintenance expense is also quite low.

- Construction time is fast because corrugated iron is cut to length depending on demand; it is pretty convenient for assembly and construction.

- High durability and safety. Steel and corrugated iron roofs are firmly bonded together by durable welds so that the service life will be extended. In addition, a corrugated iron roof is also quite an environmentally friendly material.

- Versatility and convenience, as the steel frame is flexible.

2.4. Factory model with wall combined with corrugated iron roof

The structural factory includes corrugated iron walls roof and steel pillars. The steel pillars are poured with concrete to create a solidity to withstand all weather conditions.

The implementation of this small pre-engineered factory model will help businesses save a lot of factory construction costs. Besides, the solidity is quite high, so it is very suitable for warehouses. Similarly, you will feel that your factory is larger than the actual area. Moreover, this model helps reduce a building’s wear and tear. Hence, it is suitable for long-term production needs.

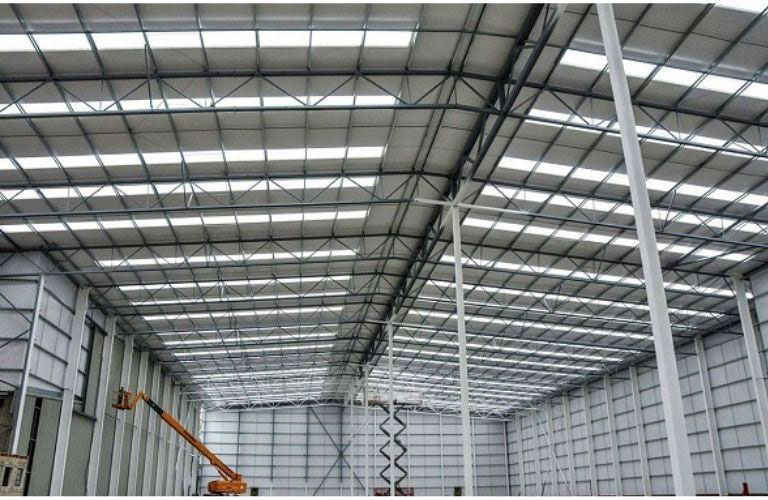

2.5. Factory model with high steel frame and roof

In this model, the wall will be built and designed quite high. During the construction process, the corrugated iron roof will be arranged with a roof to create a sense of spaciousness and safety. The steel frame system is assembled from a 2-layer anti-rust steel material to ensure high durability and certainty. This is a design pattern that receives a lot of attention from businesses today because:

- Effective control and prevention of fire and explosion.

- Thanks to the top of the roof, the factory is very airy and resistant to mold. As a result, businesses can reduce the cost of installing ventilation fan systems.

- The requirements are pretty strict about the direction, so the operation and transportation of goods are quite convenient.

2.6. Small pre-engineered factory model

The small pre-engineered factory is specially built with an all-steel pillar frame, so it has good durability to withstand the impact of environmental factors. This is an increasingly popular factory model, and many businesses choose it as a warehouse or a place to build a production chain.

This factory model has a simple design, so the construction time is fast. Moreover, it has high industrialization and excellent bearing capacity.

2.7. Simple small factory model 500m2

The factory model is suitable for small businesses to optimize cost efficiency. The model has a steel column structure and a steel truss that creates a high degree of stability and solidity. Besides, the construction time is quite fast. Usually, it only takes a few months, saving a lot of time and cost.

It is a multi-purpose factory that can be used as a warehouse for goods or a place to install production machinery and equipment.

2.8. Gorgeous factory model 1,000m2

It is the choice for small and medium-sized businesses to renovate and change the area or space in the future. Designed according to the steel column structure, the steel truss creates high aesthetics.

Businesses often use this factory model to store goods or manufacture factories. The construction process of the factory is quite fast, so the time and construction costs are not too high.

2.9. Small factory model 1,200m2

Many small and medium-sized enterprises today prefer this factory model with the ideal area. It is designed from steel columns and trusses to ensure solidity and aesthetics for the factory, so the structure is easy to assemble and dismantle. In particular, the installation cost is low, and hard costs are incurred in the implementation process.

Businesses can use it for many different needs, such as warehouses or factories. In the future, it can be easily renovated and refurbished depending on the condition of the business.

2.10. Model of a small factory made of corrugated iron

The walls and roof of this factory model are both made from corrugated iron, chosen by many businesses to save costs effectively. Construction, as well as installation time, is quite easy and fast, so it saves costs. This model has an excellent heat and sound insulation system, but it is poorly ventilated and needs to be installed with an additional ventilation system. Businesses can use it as a warehouse or a factory, depending on the purpose of use.

3. Benefits of constructing prefabricated steel frame factories

3.1. Save construction costs:

Prefabricated steel frame factories or pre fabricated building often have lower construction costs than traditional factories due to the use of lightweight materials and quick installation processes.

There is no need to use many traditional construction materials such as concrete and bricks, helping to reduce transportation and ground treatment costs.

3.2 Quick construction time:

The construction process of prefabricated steel frame factories takes place faster than the construction of other types of factories, helping businesses save time and have the ability to quickly put into production operations.

3.3 High durability and safety:

The steel frame is designed to be sturdy and has high bearing capacity, helping the factory to be durable for a long time.

The prefabricated steel frame factory meets safety standards, ensuring a safe working environment for employees.

3.4 Flexibility and Convenience:

Prefabricated steel frame factories have high flexibility, and can change structure or expand easily according to business needs.

Installation of utility systems such as electricity, water, and ventilation systems is done conveniently.

These benefits make choosing to construct prefabricated steel frame factories a smart decision for manufacturing and business enterprises.

So in this article, BMB Steel has provided you with small, cheap prefabricated factories and the most common warehouse applications with quite detailed information. Hopefully, businesses will have a more general view of choosing the right factory model for their business purposes.

>>> See more: The most detailed documents and procedures for applying for a factory construction permit

Important notes when building a factory to high standards