Integral principles when arranging factory premises

The factory is the workplace of many workers. How to utilize the factory to increase efficiency in business activities? This mainly depends on the warehouses and factories’ design and layout. Therefore, in this article, BMB Steel will provide you with some integral principles in the factory premise’s layout to have a reasonable allocation.

1. Determining factors of the factory premise’s layout

The first thing that businesses have to do is to choose a reasonable warehouse and factory location. A suitable, convenient, and cost-optimized location, as well as factory premise’s layout, depends on:

- Features of the products

- Features of the production equipment.

- Volume, performance, and production line.

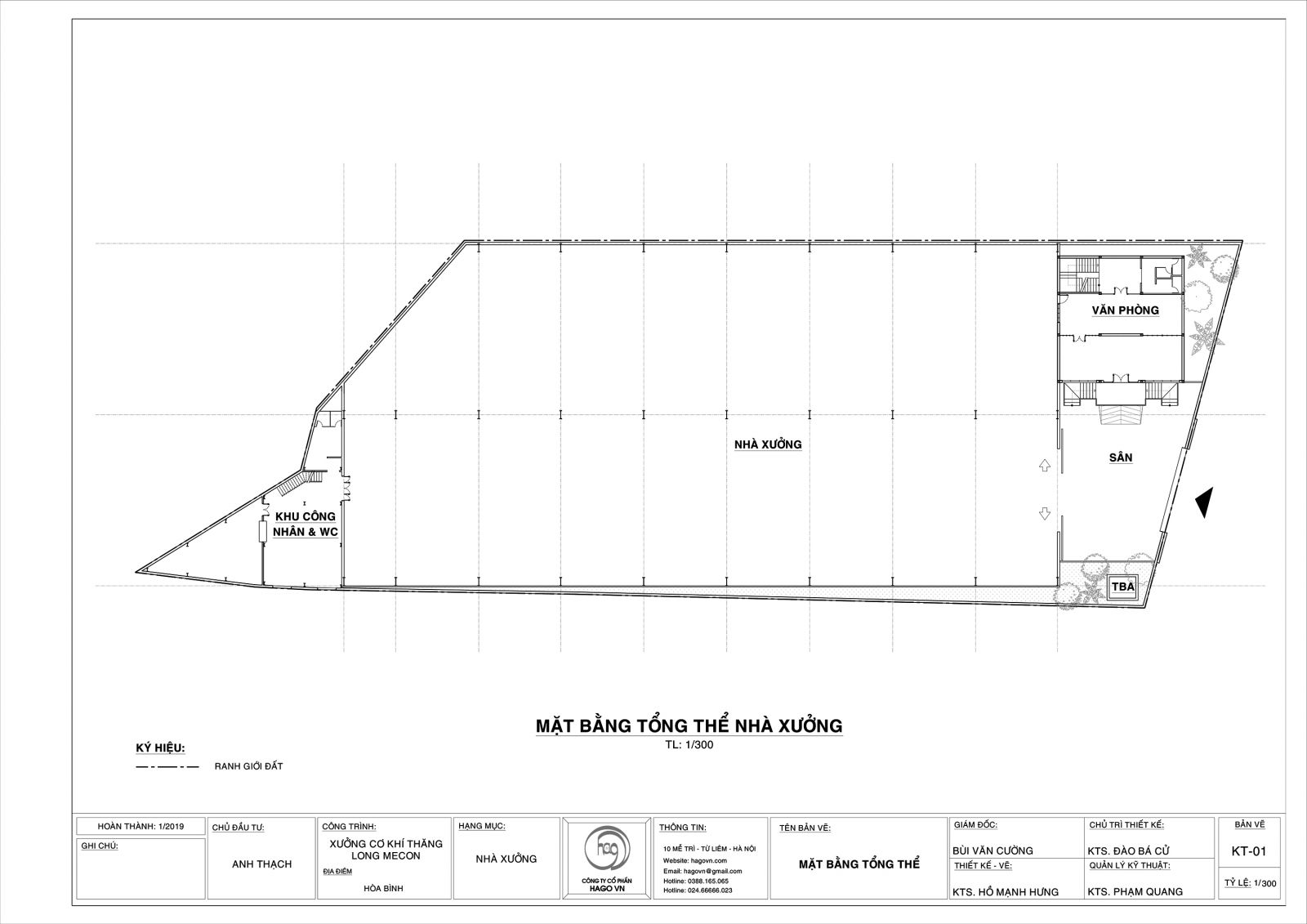

- Area of premises used (determining the production process, how many subdivisions there are, allocating the locations of zones for the convenient production line; raw material and products’ warehouses have to be placed for easy transportation, etc.)

- Labor resources.

- Guaranteed safety in production.

- Features of the goods transportation, means of transport, vehicles, etc.

Therefore, when enterprises make the decision to build factories, they should clearly identify these factors to choose a suitable location and premise’s layout.

2. Some principles of the factory premise’s layout

2.1 The safety for production and workers

- When constructing, it is required to: ensure safety and create a favorable environment for workers, machinery, and equipment; ensure the product quality assurance; solid steel structure strictly follow the regulations such as explosion-proof, heat-proof, vibration-proof, noise-proof, and anti-explosion dust, etc.

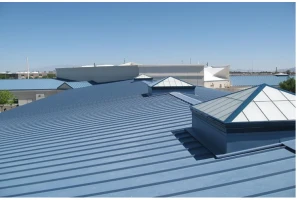

- When designing pre fabricated building, it is vital to ensure ventilation and prior to absorbing more natural light. Conventionally, factories generate a lot of dust, smoke, toxic fumes, etc., so they should be located in a separate area, avoiding populated areas.

- Warehouses containing flammable and explosive materials must be located away from production areas. They must always be fully equipped with fire prevention and fighting equipment. If your product is flammable, you can choose to build your factory in a pre-engineered steel building to limit fire and for more ventilation.

- Devices that make loud noises can affect other devices and easily affect product quality, so they should not be placed near expensive equipment.

2.2 Compliance with the process

Factories are arranged according to the order of the product manufacturing technology process. The product has to pass through many factories in an orderly. Therefore, the first factory should be located near the raw material warehouse, and the last factory should be located near the finished goods warehouse.

Two workshops that have a relation in exchange of products should be arranged next to each other to facilitate the transportation of raw materials and finished products. Besides, the finished goods warehouses should be located near the main roads or highways.

2.3 Ensure the ability of production expanding

When choosing the location and factory layout. You should consider the possibility of future expansion.

Due to the need for development, the expansion will lead to an increase in the production output and other products, so expanding the production area is inevitable.

2.4 Utilize the space and premise

Making use of the available areas may assist businesses in minimizing incurred expenses.

Currently, many factories have used overhead conveyors as equipment for their warehouses.

2.5 Ensure system flexibility

When expanding or arranging the production premises, it is significant to take into account that the equipment system will be changed. Thus, it must be calculated so that these changes can be made quickly without incurred cost or production disruption.

2.6 Avoid and reduce the opposite-direction transportation

This problem not only increases the distances but also causes congestion in the transportation process.

Hopefully, BMB Steel has provided you with helpful information about the factory premise’s layout with the above information. Besides, you can refer to more factory drawings and pre-engineered warehouse models to choose suitable ones for your own buildings!