Crucial notes to build a high standard factory

- 1. Detailed factory construction process

- 2. What should you pay attention to during the factory construction process?

- 3. Factory construction costs and budget

- 4. Contractor selection and project management

- 5. Laws and regulations on factory construction

- 6. Maintenance and management of the factory after construction

- 7. Reputable factory construction unit in Ho Chi Minh City

Recently, office buildings and pre-engineered steel factories have increasingly focused on meeting production and business needs. Especially, safety during construction is a primary concern. Therefore, the issue of making the construction process safe, economical, and high-quality is seriously paid attention to. To learn more, let’s explore with BMB Steel the following notes when building a factory in the article below.

1. Detailed factory construction process

The complete and detailed factory construction process includes the following steps:

- Step 1: Prepare legal documents

Apply for construction permits, and ensure compliance with regulations and planning.

- Step 2: Planning and design

Determine goals, and technical requirements and create detailed plans.

- Step 3: Prepare the ground

Leveling and preparing land and facilities.

- Step 4: Construction of foundation and factory frame

Build a solid foundation, and install a steel frame or reinforced concrete.

- Step 5: Build and install infrastructure

Construction of electrical, water, and fire protection systems, and necessary equipment.

- Step 6: Complete and accept

Check the quality of the project, complete the items, and conduct acceptance.

Each step needs to be done carefully, strictly following construction standards to ensure the safety and efficiency of the project.

2. What should you pay attention to during the factory construction process?

2.1 Aperture in construction

Aperture in construction is the distance from one edge of the column to the other, or another definition is the width of the factory.

Depending on the land area and production needs, the construction aperture of the enterprise will be different. For example: aperture 15, 20, 30,...

2.2 Factory aperture

Factory aperture is the distance from the edge of the right boundary column to the edge of the left boundary column calculated horizontally across the factory, also known as the width of the factory. Factory aperture as well as construction aperture are calculated with many different sizes such as 15m, 20m, 25m,...

2.3 Factory location

It is recommended to choose a well-ventilated and cool location to avoid affecting work performance and protect the environment.

You should choose a location surrounded by many trees for fresh air.

Determine the scale and area of the factory.

Arrange the total area by the current industrial diagram and the investor's expansion plan.

Select locations where the factory scale can later be expanded.

The factory construction location is convenient for transportation, access to raw materials, and compatibility with urban planning.

2.4 Design standards in factory construction

Determining the location to build a factory also needs to be carefully calculated to avoid wanting to expand the scale in the future, and especially must comply with the regulations in the industrial construction standards as follows:

Vietnam Construction Code, Volume 1 issued by the Ministry of Construction, accompanied by Decision No. 682/BXD-CSXD dated December 14, 1996.

Vietnam Construction Code Volume 2.3 issued by the Ministry of Construction, accompanied by Decision No. 439/QD-BXD dated September 25, 1997.

Standards by each category:

- The foundation is built according to TCVN 2737:1995 standards.

- In the foundation area, drilled piles must be firmly packed.

- The height of the foundation must be lower than the ground level.

- The foundation needs to be placed with expansion joints created.

- Materials: concrete, cement tiled floor,...

Roof, roof door

- The roof is designed with a slope that depends on the roof material.

- Factories with roof slopes of less than 8% need to design concrete heat gaps.

- Roof doors are designed to combine with ventilation and lighting systems and must not be wider than 84m.

- Roof doors need to be glazed vertically.

Walls, partitions

There are different types: load-bearing walls, frame insert walls, etc. Walls can be made from bricks, stones, asbestos panels, etc. Brick walls require the use of a waterproofing layer. Walls between workshops need to be installed easily for disassembly to meet the requirements of structural changes and machinery repairs.

Windows, doors

- Windows and doors must provide good light and ventilation.

- The window height must not exceed 2.4m

- For storm protection, glass windows will be installed higher than 2.4m, with fixed frames.

In addition to factory design standards, you also need to aim for efficiency and flexibility. This includes optimizing workspaces, ensuring worker safety and health, as well as flexibility to be able to adapt to future changes in production scale or technology.

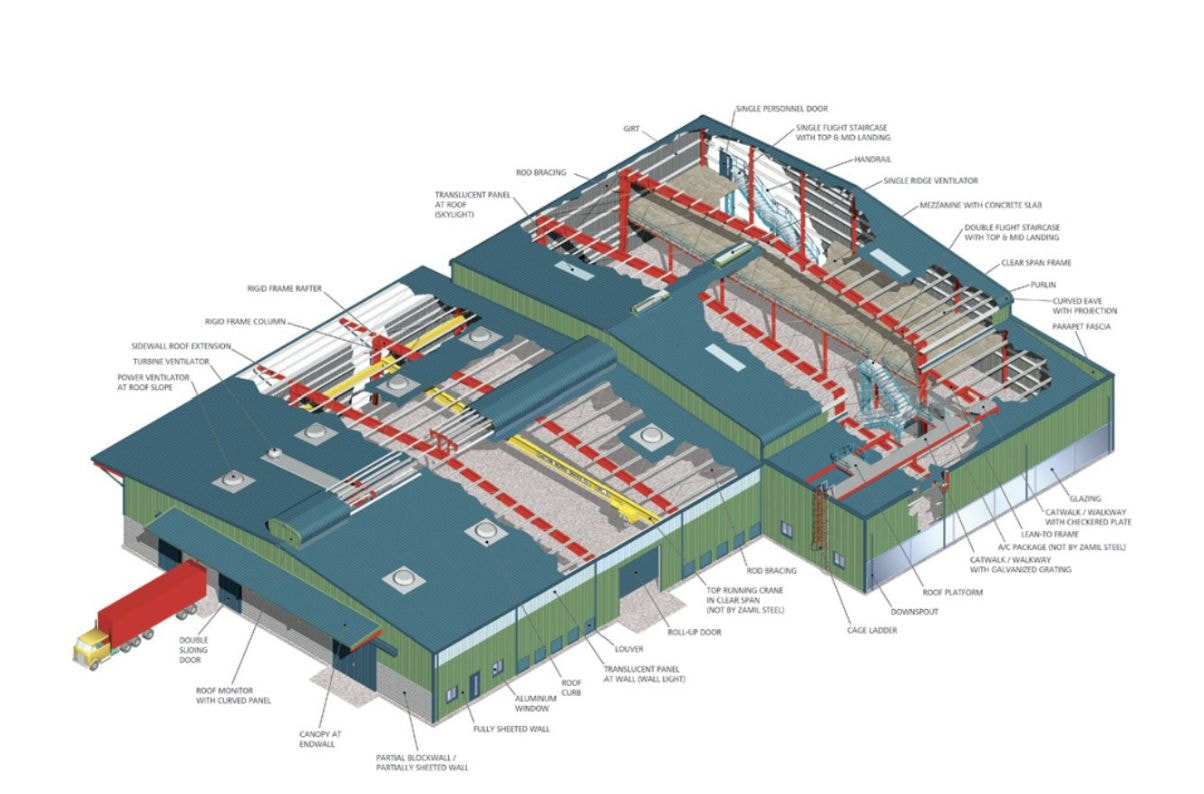

2.5 Factory structure

Each factory has its space structure and each space takes on separate functions, so customers need to design it to properly promote its functions.

2.5.1 Ceiling system

The erection of the roof and ceiling is carried out after the erection of the main frame has been completed and aligned correctly. The tie rod bolts have been tightened. During the construction process of the factory and ceiling system, customers need to pay special attention to the joints of the straight insulation cotton, so as not to be pulled or wrinkled. Ensures the durability of the ceiling.

2.5.2 House Foundation System

- The foundation is the most important structure of any construction project.

- When constructing the foundation design, special attention should be paid to expressing technical specifications.

- Materials for making nails must meet the standards and regulations according to TCVN and international standards

- Note in choosing the location for the foundation, for each different type of ground, we have different ways to choose the type of foundation: for factories built on weak soil or mud, you should use the solution of pressed piles and piles. drilling,... but for factories built on hard ground, just build the foundation normally.

2.5.3 Door System

- Installing the door system is also very important.

- Make sure the door is firmly mounted against the wall and easy to open. Door installation techniques must be very careful.

- If the door is not installed carefully or correctly, after completion, the door will tilt or the door will fall off the rail.

2.5.4 Partition wall system

The partition wall system must also be designed and constructed extremely meticulously, ensuring the stability of the factory. Ensure the work of the construction party and the pre-engineered steel building installation party are consistent.

2.5.5 Ventilation system

The system ensures stable air circulation. The system can be installed on ceilings, roofs, or basements of manufacturing plants, petrochemical refineries, etc. Essential notes when installing ventilation systems: calculate the required airflow and suction volume. How much to install the most suitable system? If the installation space is not enough, the air vents can be increased in size, and a fan with low noise so that the factory does not have noise that affects the production process.

2.5.6 Lighting system

The lighting system is a very important part of the factory. Depending on the type of factory, the level of lighting requirements is different. For each area such as warehouse, common area, production area,... when designing, it is necessary to carefully study the characteristics of the factory and choose the appropriate brightness.

Select appropriate lighting for each area according to TCVN 7114-2008. Make the most of natural light. You should choose LED lights to save costs and energy, and have higher lighting efficiency.

3. Factory construction costs and budget

Factory construction or pre fabricated building costs and budgets depend on many factors such as project scale, construction materials, technical design, and labor costs. Budgeting needs to take into account both direct (materials, labor) and indirect (project management, legal) costs. It is necessary to carry out a detailed cost assessment to avoid unnecessary problems, and at the same time look for cost-saving solutions without affecting the quality of the project.

4. Contractor selection and project management

When selecting a contractor and managing pre engineered steel building project, the following criteria should be considered:

4.1 Criteria for Selecting Reputable Contractors

Experience and reputation in the market.

Financial capacity and quality management system.

Implemented projects and feedback from customers.

Comply with legal and safety standards.

4.2 Managing project quality and progress

Establish and monitor plans and implementation progress.

Periodically inspect and evaluate project quality.

Close coordination between investors, contractors, and related parties.

Timely handling arising problems, ensuring the project is completed on time and meets requirements.

5. Laws and regulations on factory construction

In factory construction, legal and regulatory compliance is a factor that cannot be ignored. First, it is necessary to apply for a construction permit from the authorities, ensuring that the project complies with planning and regulatory standards. Labor safety standards must be strictly followed to ensure a safe working environment for workers.

In addition, environmental standards should also be considered, including waste treatment and pollution mitigation. Close coordination with authorities helps ensure the project not only complies with the law but also avoids unwanted legal risks.

6. Maintenance and management of the factory after construction

Maintenance and management of the factory after construction is a key factor in ensuring continuous and effective operations:

6.1 Periodic maintenance instructions:

Set up a periodic maintenance schedule for each factory part.

Inspect and maintain machinery, equipment, electrical systems, and infrastructure.

Record and monitor the maintenance process to promptly detect and handle problems.

6.2 Effective management and operation of the factory:

Apply quality management systems such as ISO to control and improve work processes.

Use factory management software to track progress, and manage inventory and material flow.

Training and developing skills for management and staff to improve work performance.

7. Reputable factory construction unit in Ho Chi Minh City

If you are still wondering about things to note when building a factory, come to BMB Steel. BMB Steel and its professional team will answer and advise you most enthusiastically and thoughtfully. In addition, BMB Steel is also one of the most prestigious steel structures and factory construction units in Ho Chi Minh City as it continuously develops domestically and internationally and receives much trust from investors. big. BMB Steel has become a name that many investors think of when they want to construct factories.

Factories play an important role in the modern economy. As the heart of all production and storage activities, the factory not only plays a central role in the supply chain but also directly affects productivity and business performance. Therefore, factory construction not only requires carefulness in each step of design and construction but also needs to be approached professionally. This professionalism not only ensures the quality and safety of the project but also creates a solid foundation for the sustainable development of the business.